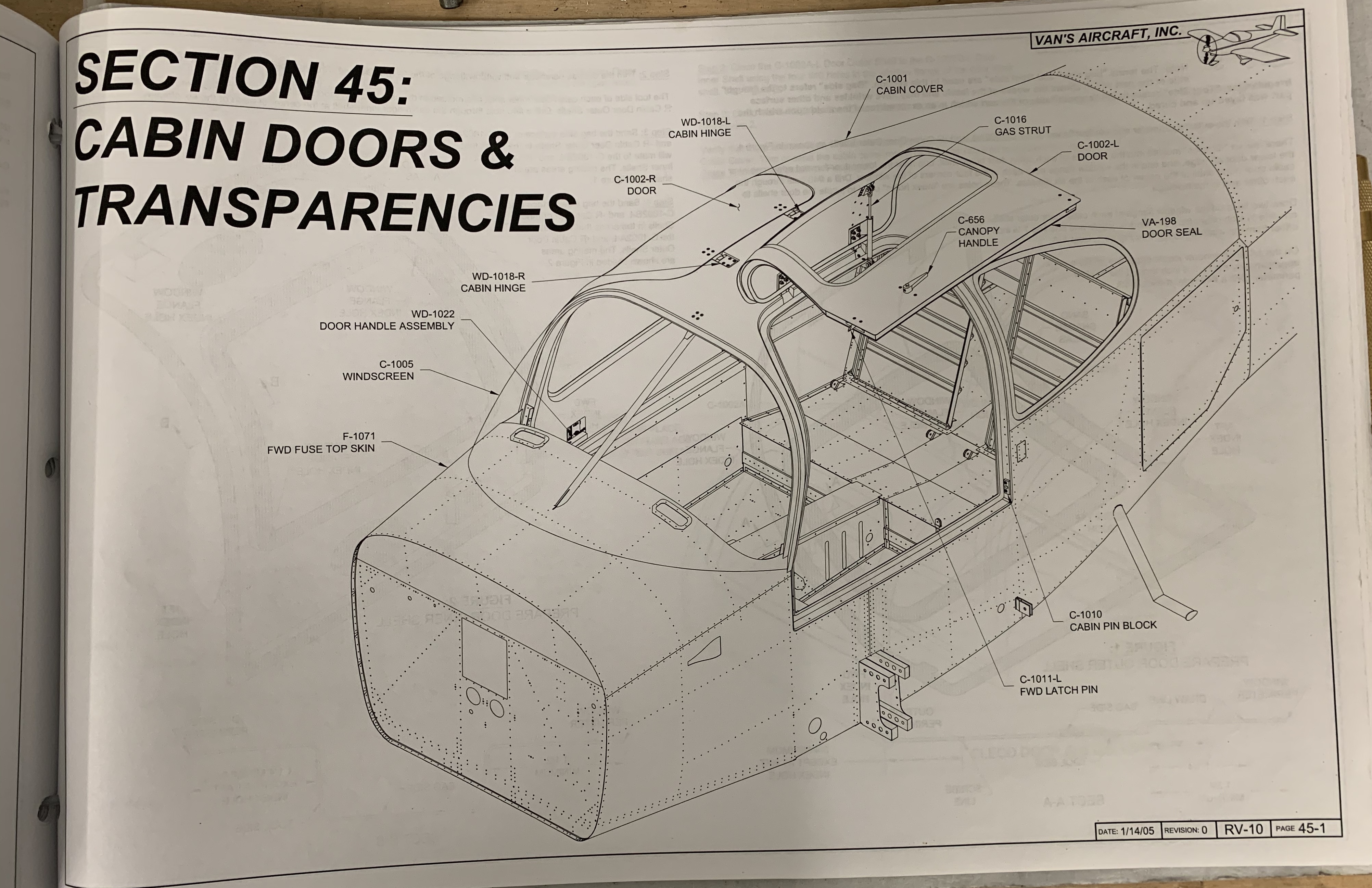

Knowing that there will likely be several posts about doors… I will do posts in “parts” Otherwise I will quickly run out of ideas for post titles. Unless, of course, there’s something more clever that comes to mind at the time.

I’ve decided to postpone bonding the doors together just yet to get the Planearound latch , door handle mechanism, and Aerosport exterior handles all installed. Nevertheless, I did sand down the spots on each shell depicted on the plans that will touch and bond together.

Trying out a sanding pad on a pneumatic die grinder

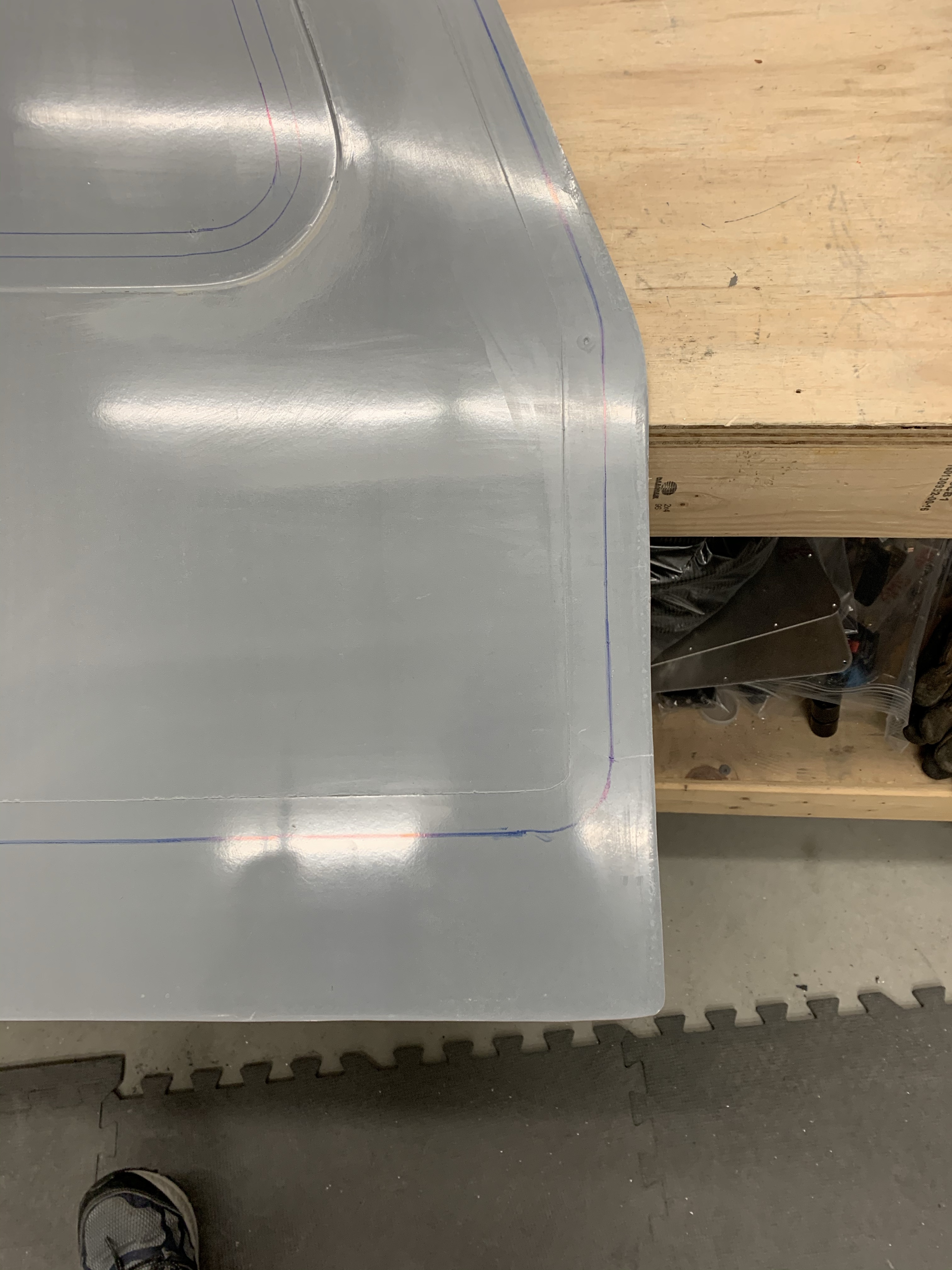

Next you put the door shells together using the dimpled index holes in the fiberglass that were drilled in each half. Like so many others, mine didn’t line up very well. The aft index hole lined up okay, as did the forward index hole (although it wasn’t aligned with the fuselage hole in the plans). It was aligned with the last hole of the upper forward fuselage about 4 holes up from what the plans say. The index holes in the corners of the window were pretty much useless. There was 1 on 1 door that did line up and another on the other door that was close, but the others weren’t even close. Doing some reading this seems to be fine, you basically make sure the door is centered the best you can. Mine seemed to be fine using the aft and forward index holes, so I went with that.

Right door attached to forward and aft index holes

Then you use a hole finder (seeing I had one) to perfectly match drill the open rivet holes in the fuselage with the door shells. This allows a cleko to be put in and the doors held tight to the fuselage.

Hole finder to drill the door shells perfectly.

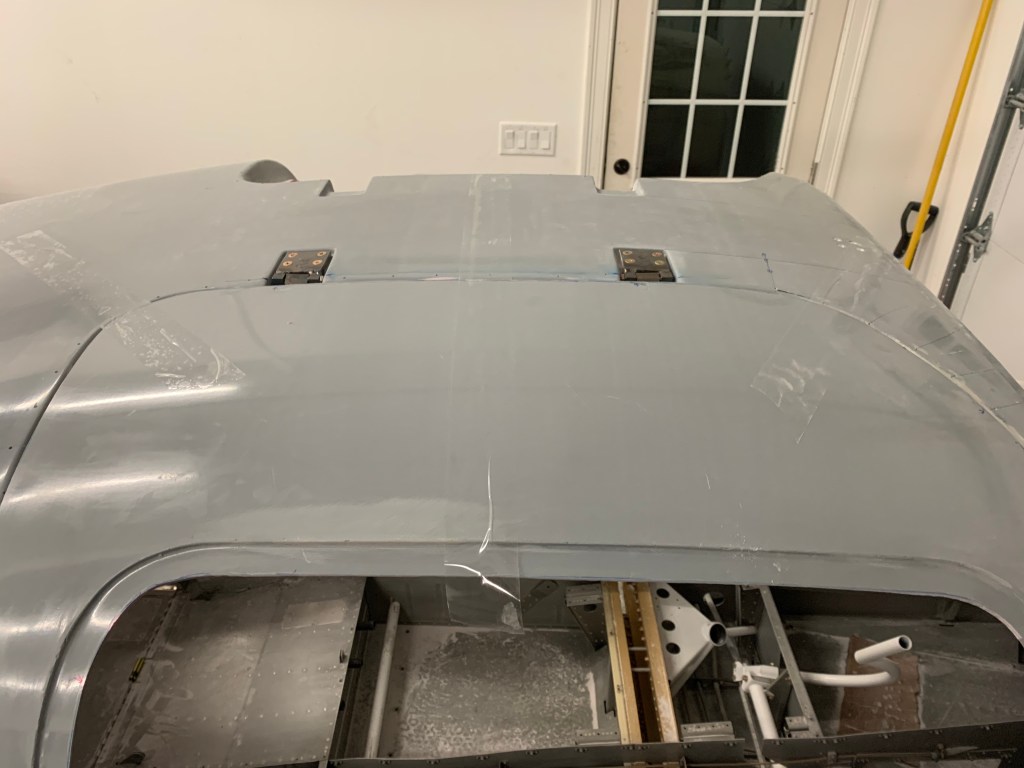

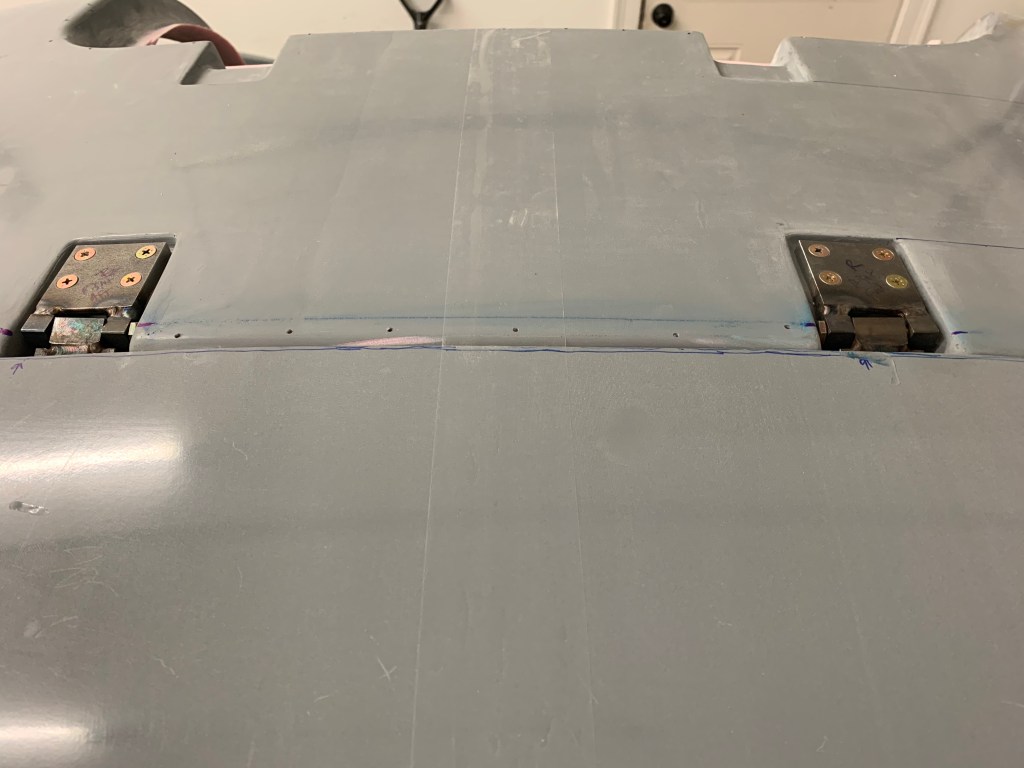

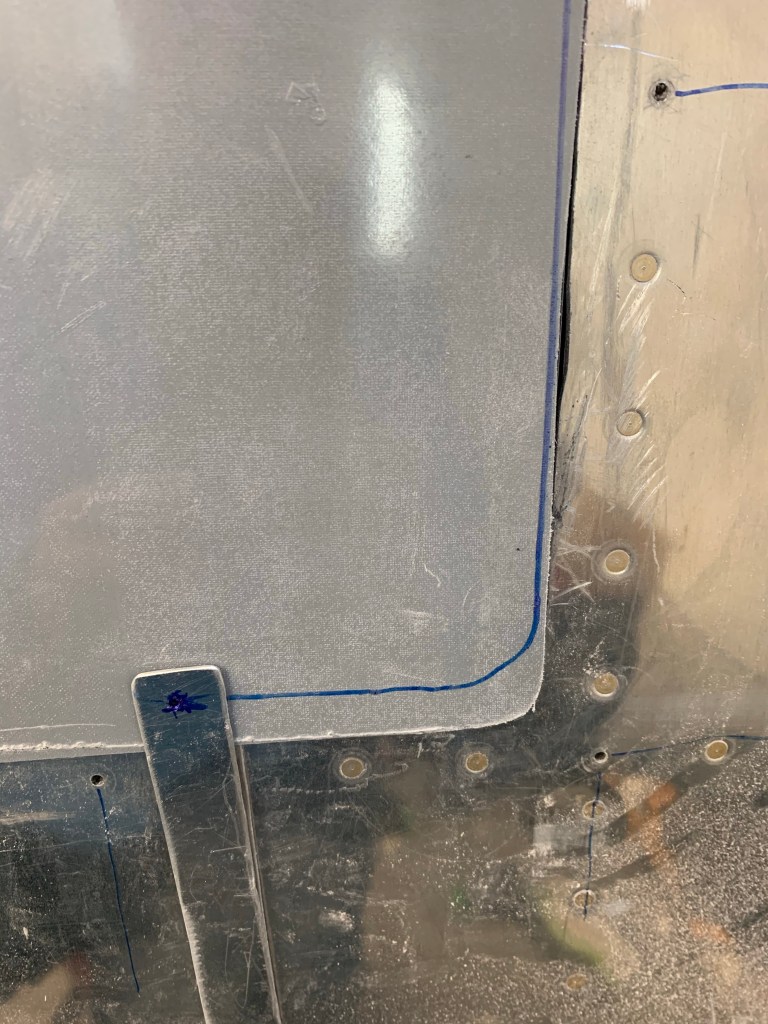

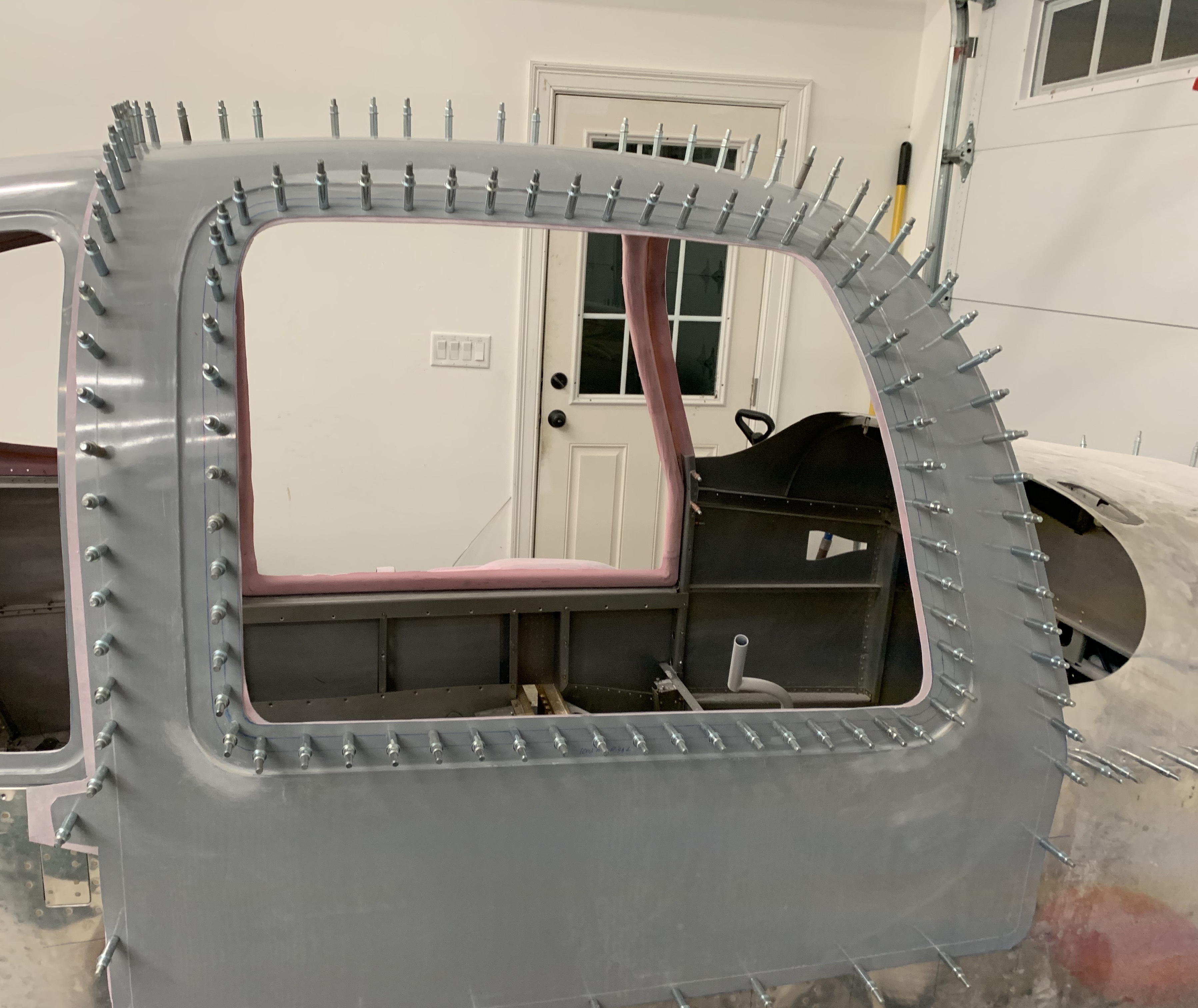

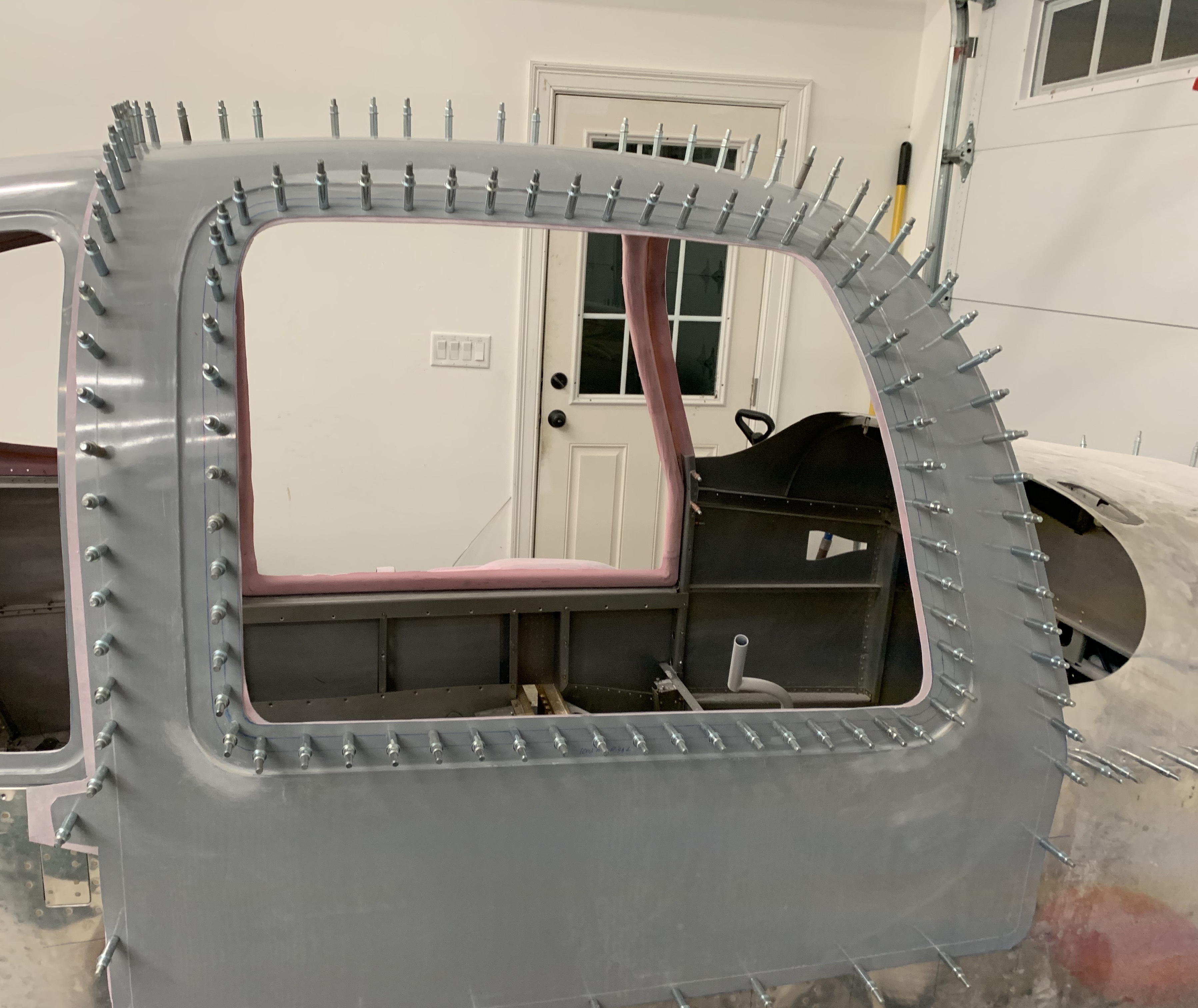

Once the bottom holes were done along the fuselage, you’re supposed to tape the upper part of the door to the cabin top. Then match drill and cleko the window opening. I had read of others drilling holes along the door pillars and cabin top to hold the door shells very tight to the fuse and not have to rely on tape. To me, this is a much better method that allows the door shells to hold the shape of the door opening much more precisely. It may not be obvious from the picture, but the door shells are still oversized for bonding so they make contact with the outer surface of the door opening in the cabin top. This is what allows the door to be shaped to the cabin top when bonding.

Right door attached to cabin top/fuse.

Left door done too showing clamps that were used while drilling the pillars.

A view from the front after both doors done.

Inside of pilot’s door

An example of extra holes drilled in the cabin top/door pillars

Next up was to drill and attach the door strut stiffener. This is a simple match drill holes.

I then hopped over to start working on installing the Planearound center latch system. First is locating the proper position, cutting out a slot on the bottom of the raised door edge, and also drilling and slotting a hole for the shaft.

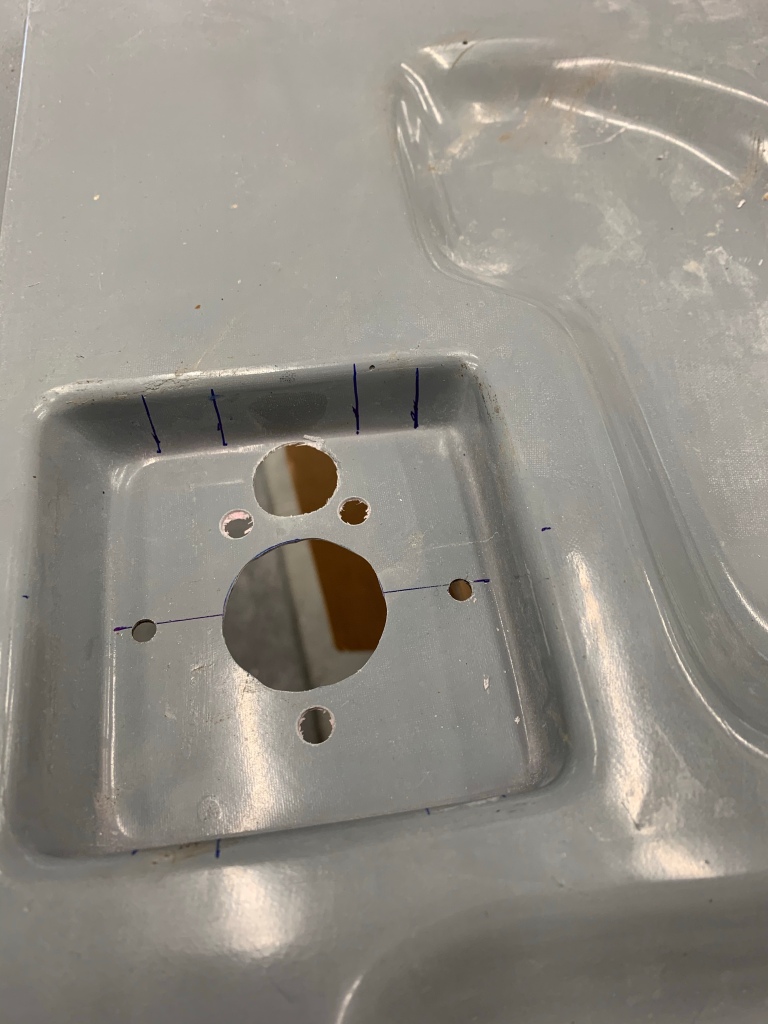

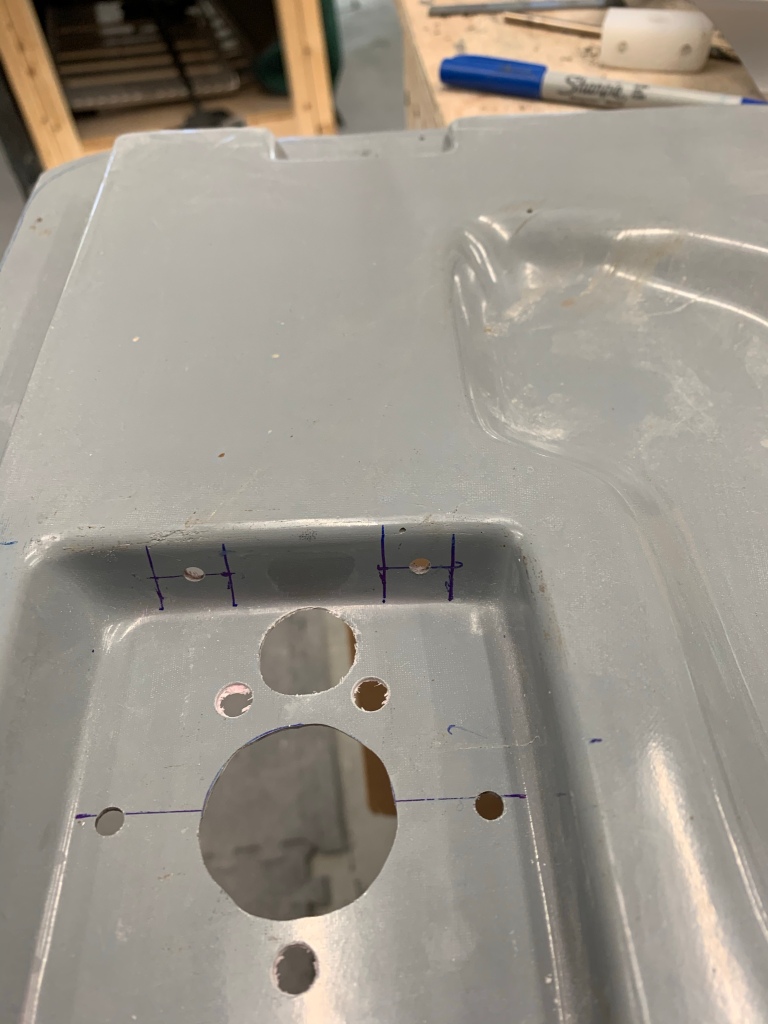

center cam gearbox and markings for the cut.

After drilling a 1/2″ hole, and making a slot for the shaft in the gearbox.

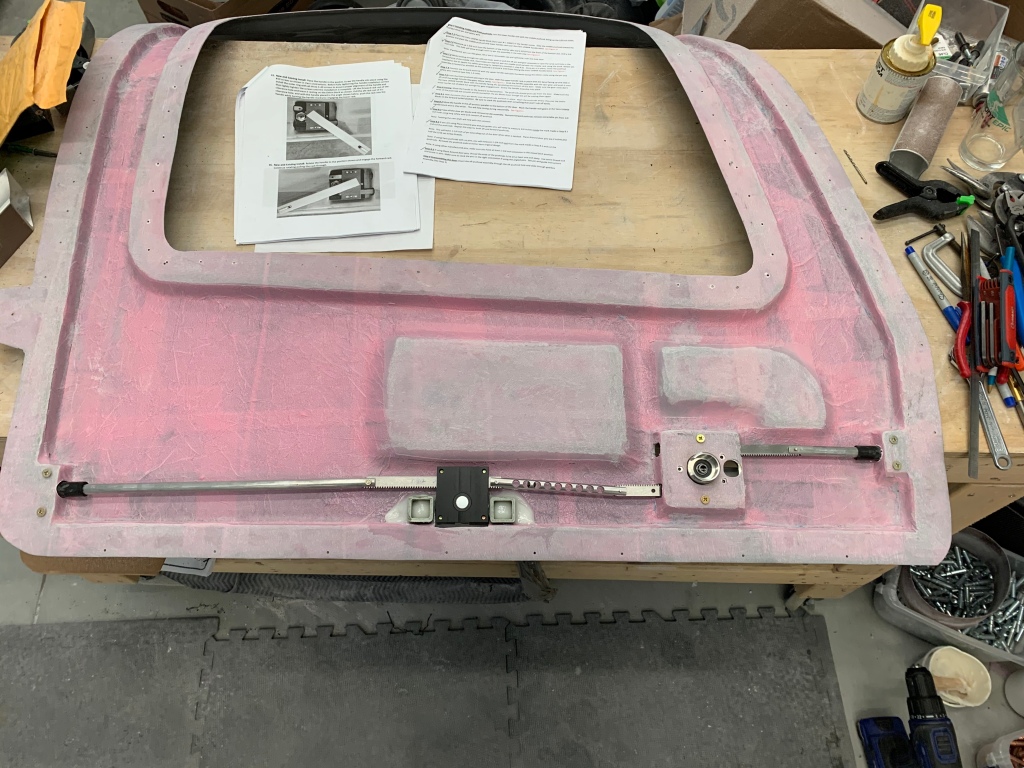

I then drilled the 4 holes that will hold the gearbox in place and countersunk them in each door and prepped for attaching the supports for the cut area of the door. I mixed up some Epoxy and cabosil first as I will attach both the door strut and these door cut supports all at once. Once I did the door strut supports with Expoy and Cabosil, I didn’t have too much left, so I added more epoxy and thicken it up with flox. So I ended up with a mostly Epoxy and flox mix with a tad bit of cabosil too.. No big deal. I wrapped the gearbox in packing tape so it doesn’t accidentally get adhered to the structure and added a generous blob in each corner with the support pieces in place.

Gearbox taped and supports added with Epoxy/Flox.

Door Strut support plate cabosil’ed in place.

Now I’ll wait for these pieces to fully cure before continuing.