Just before Memorial Day, Evoke let me know that the plane was ready to be picked up! Initially, the plan was for the Friday before, however, that was pushed to Memorial Day itself due to wanting the sealant to cure over the weekend.

I purchased tickets to fly commercially down to Atlanta on Sunday, and then rented a one way car from Atlanta to Gadsden. I checked into the Hotel, went to dinner downtown.. and waited for Monday morning to come for the big reveal.

Monday morning, I arrived shortly after 9am and was greeted by the team. Some with cameras and video rolling, others working on buffing the spinner. As Jonathan says, we don’t stop working on it until it leaves. I sort of felt bad, it being Memorial Day and all, however, several members of the Evoke team were there that day.

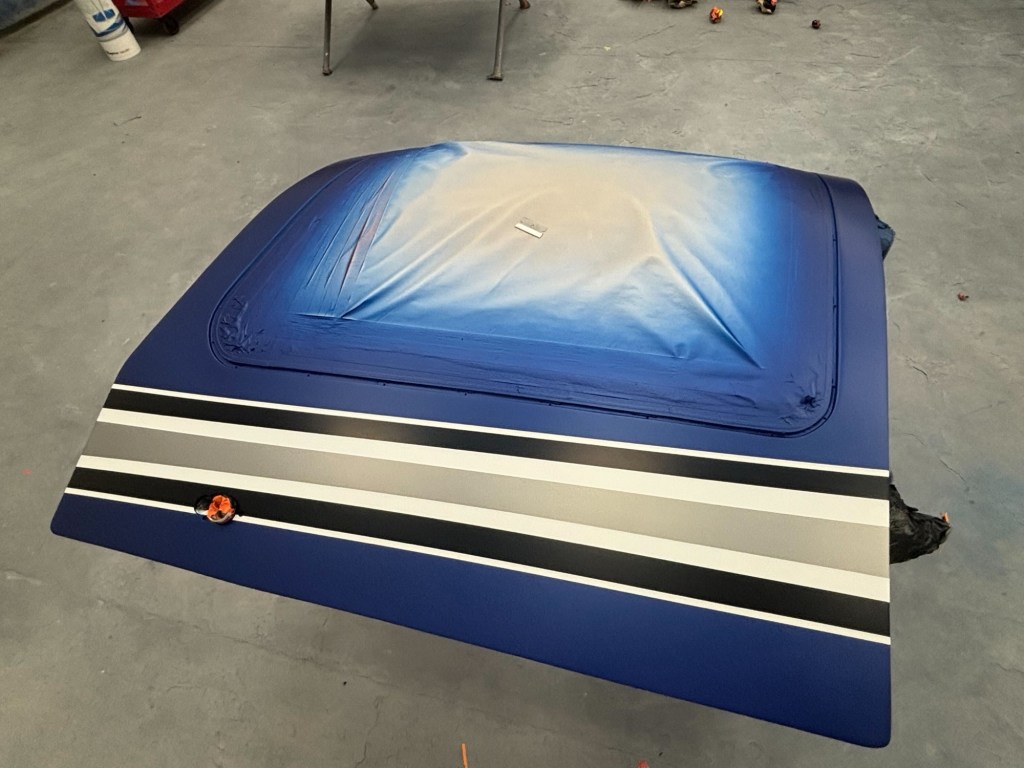

I was in awe of the finished product. It was simply perfect. Lots of areas that I left passable, but rough, were now perfect. Very happy with the color choices and how the blue came out.

Below are some of the initial pics I took while it was still sitting in the drop off and delivery hangar.

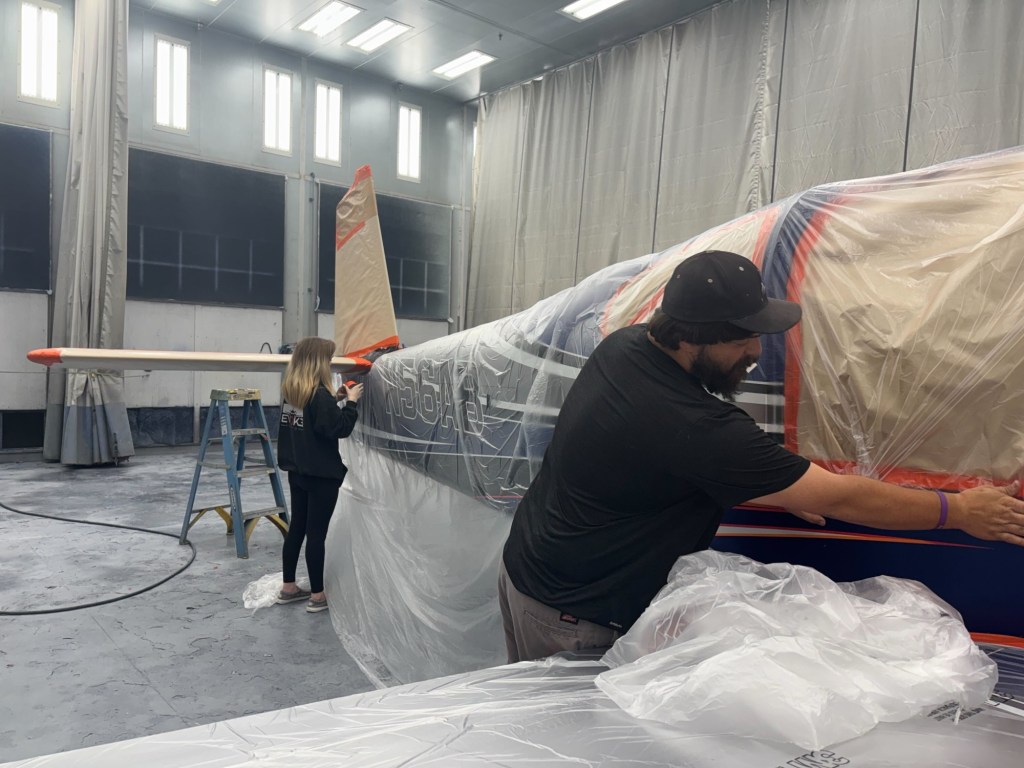

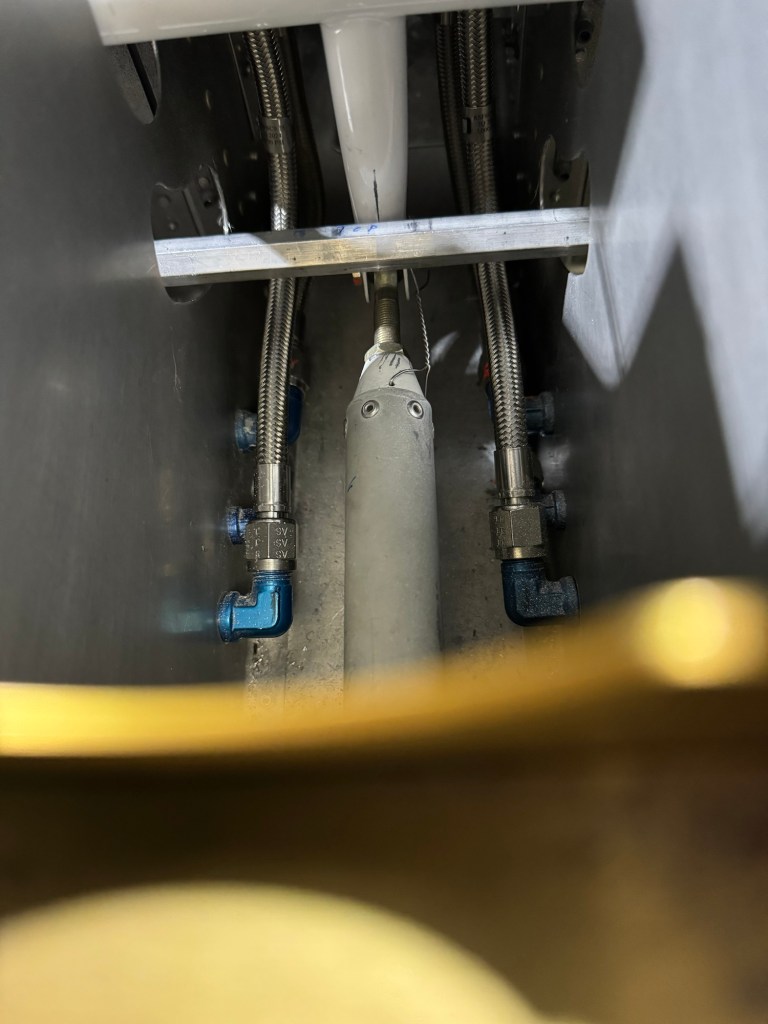

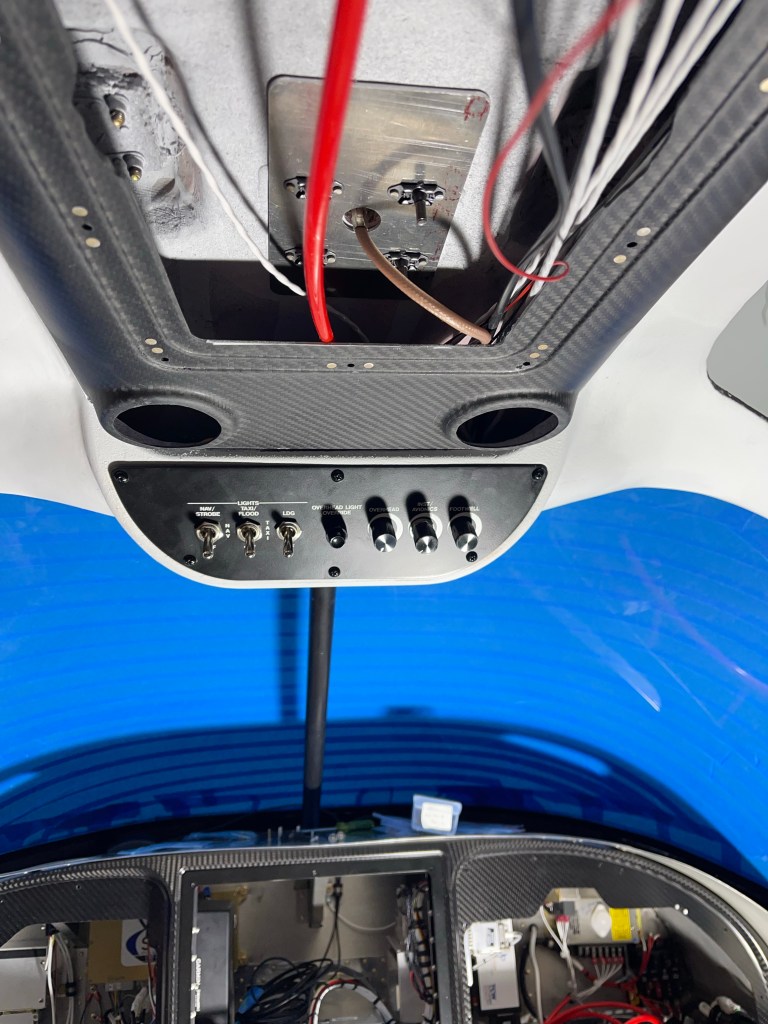

David assisted me in removing cover plates and other things to take a good look at the airplane for a preflight. Seeing all the control surfaces were removed, I really wanted to look over all the push rods etc… Everything was in order. David is the one person who takes the planes apart, takes photos of the process for documentation and reassembly purposes, and puts them back together at the end. That philosophy certainly helps when it comes to making sure things are put back together correctly. It also helps that they have painted tons of RV’s and are very familiar with them. After everything checked out, Johnathan and I finished a couple of last minute items, and then I re-checked the weather..

The weather was pretty socked in earlier in the day.. There was a stationary front over the entire state of AL. Everything around was very marginal at best.. Ceilings were 1500-1800′ in the general area. I had been looking at the VFR sectional charts for what I’d need for ceilings to go VFR.. I really wanted 2500-3000′, and I didn’t have it. I really wanted the first flight after paint to be VFR. I was sort of treating it like a maintenance flight, seeing flight surfaces were removed… Last thing I wanted was to launch into IMC immediately..

Thankfully just before noon, things were starting to break up as you can see in the picture below. It was scattered to broken at 1800′ with some large holes and blue sky above. I decided to give it a go and climb up through it to get on top. I knew once I got to Tennesse/Kentucky area it was going to be severe clear the rest of the way home. The path to the east towards Atlanta and Virgina area was really socked in and IFR all day.. So I chose to go north at first and then up the western side of the mountains headed for the Pittsburgh, PA area for a first stop. So we pulled the plane out..

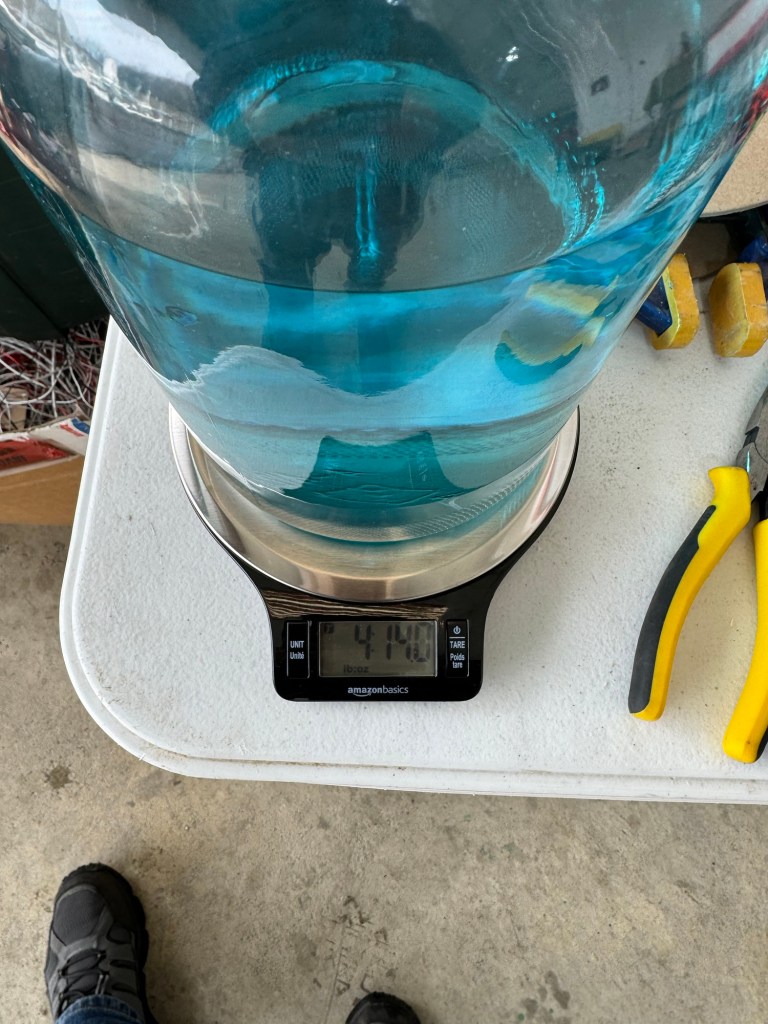

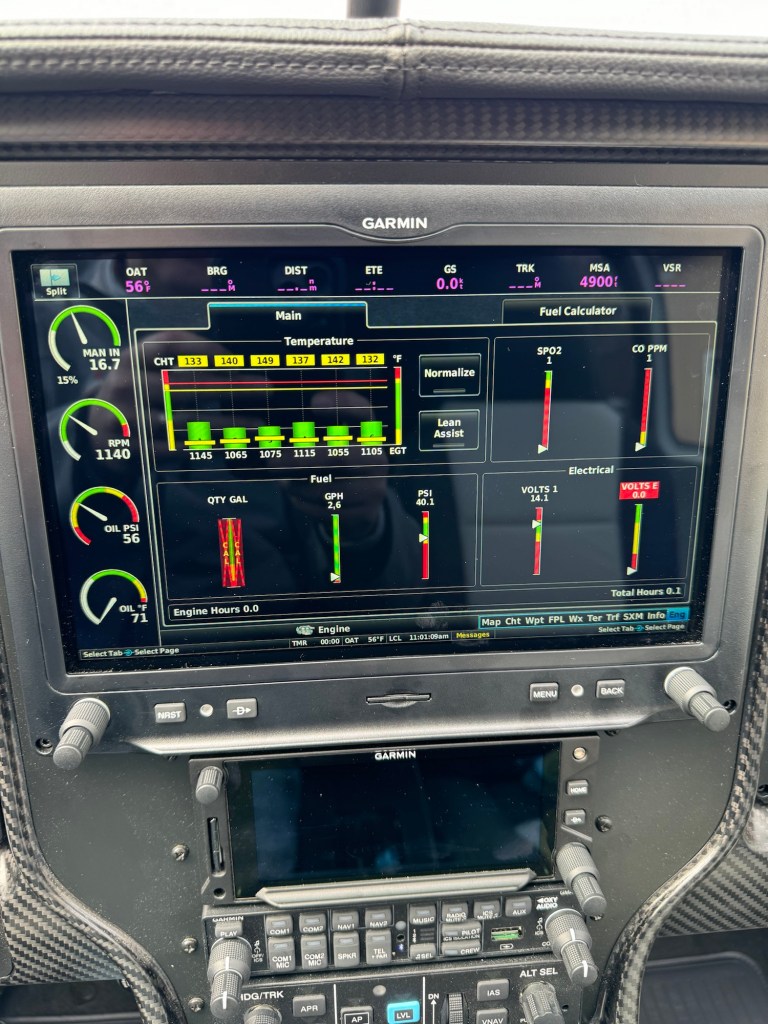

Seeing it was Memorial day, the gas truck wasn’t around, so I had to use the self serve.. A couple of hiccups happened here.. I initially went to start the engine, and it fired right up, however it ran really rough and quit.. Same thing happened again… before I realized that my gas gauge was showing empty on the right tank, which I thought.. hmm that can’t be right. I only flew a little over an hour on my last leg to get here.. I look down, and I’ve got the right tank selected… hmm lets try the left.. Much better..

I taxi over to the self serve and open the right tank. Sure enough, bone dry.. That’s odd.. As it turns out, I had a weeping rivet that they fixed prior to paint which necessitated draining the tank. I then go to fill up and the self serve pump isn’t working. It’s not powered on for some reason.. We suspect the thunder and lightning storm the previous night might have tripped something.. There was someone mowing the grass, so we were able to flag him down and he helped to reset the pump and got it working.. For a short time there I was thinking great.. I’m going to be stuck here another day because I can’t get gas on a Holiday.. No way I’m taking off with a bone dry tank.. that’s just asking for trouble.

After filling up, the clouds are letting more and more sun through and it’s hot and really humid out on the ramp.. I get loaded up and head out.. Jonathan captured the taxi and initial departure.

A couple of pics of the wings in various light conditions.

I ended up climbing up to 7500′ on top of the clouds.. As I got further north, the scattered/broken layer became a solid undercast below me, but about 70 miles later I crossed over the edge of the frontal boundary and the clouds below disappeared. into clear and a million. I ended up landing in Allegheny County just outside of Pittsburg, PA after a 3.5 hour first leg. Atlantic Aviation there was great.. They topped me off, I hit the bathroom and grabbed a hot dog and some peach tea they had.. Made for an excellent quick turn dinner. I then departed for the last leg home, which took me 3 hours. So 6.5 hours total to get home. The last leg had a few storms starting to pop up. I only had to deviate once about 20 degrees for 15 miles or so and once I got around that area of heavy precipitation, I pointed back direct home and any isolated cells that were around were far enough to the left or right that I didn’t need to deviate again.. All-in-all, a pretty uneventful flight and everything worked perfectly.

Below you can see the freshly painted bird tucked away back in the hangar.. The condition inspection is due at the end of May, so I basically just started working on it the next day to get it over with. That’s mostly over now as I write this, with the exception of a couple of minor things to finish up.

I can’t thank the Evoke team enough for making a vision turn into reality. The plane I built in my garage is now perfect. And while I say “it’s done”, we all know, it’s never really ever done.

Looking forward to the continued flight adventures that can now commence.