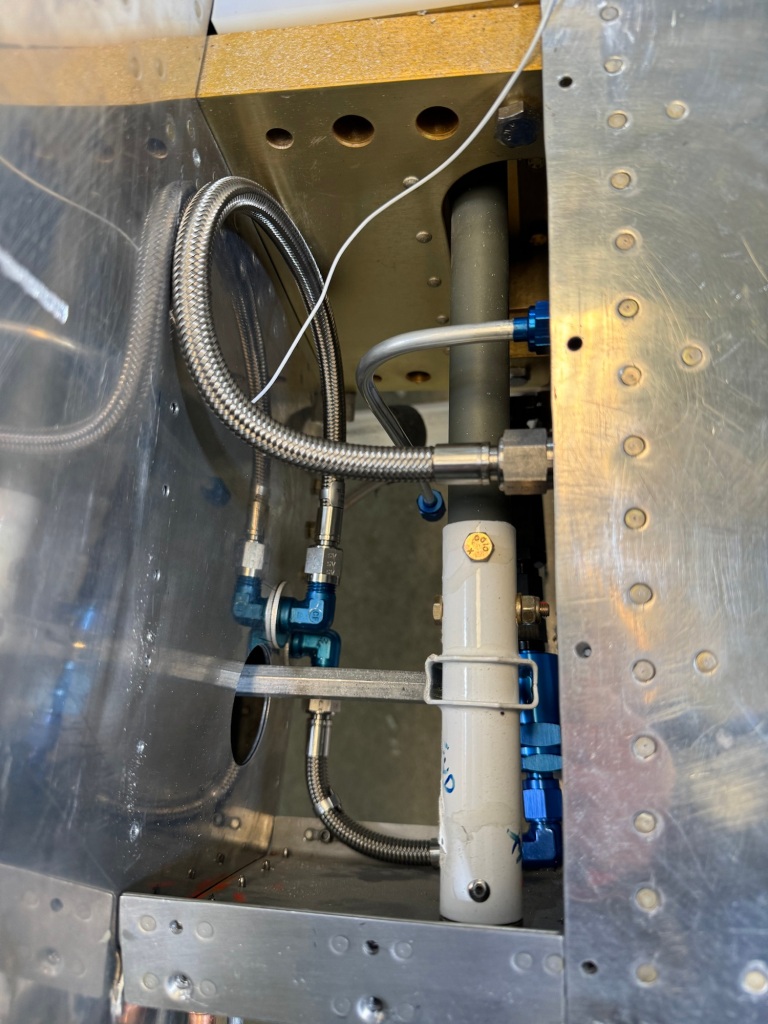

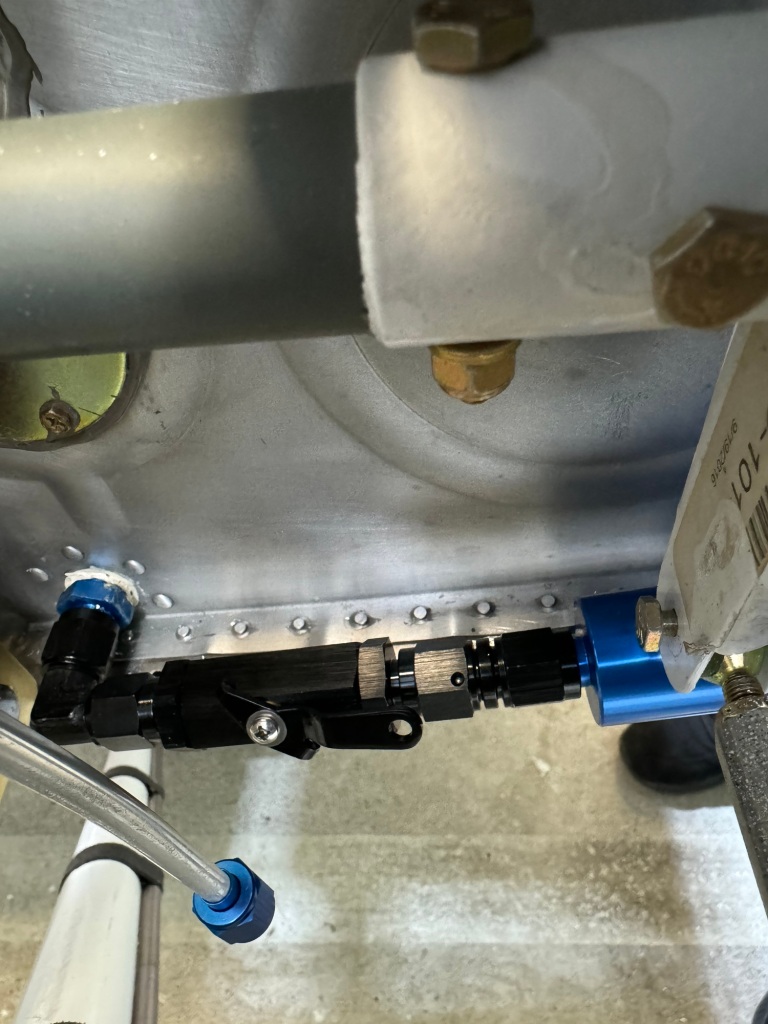

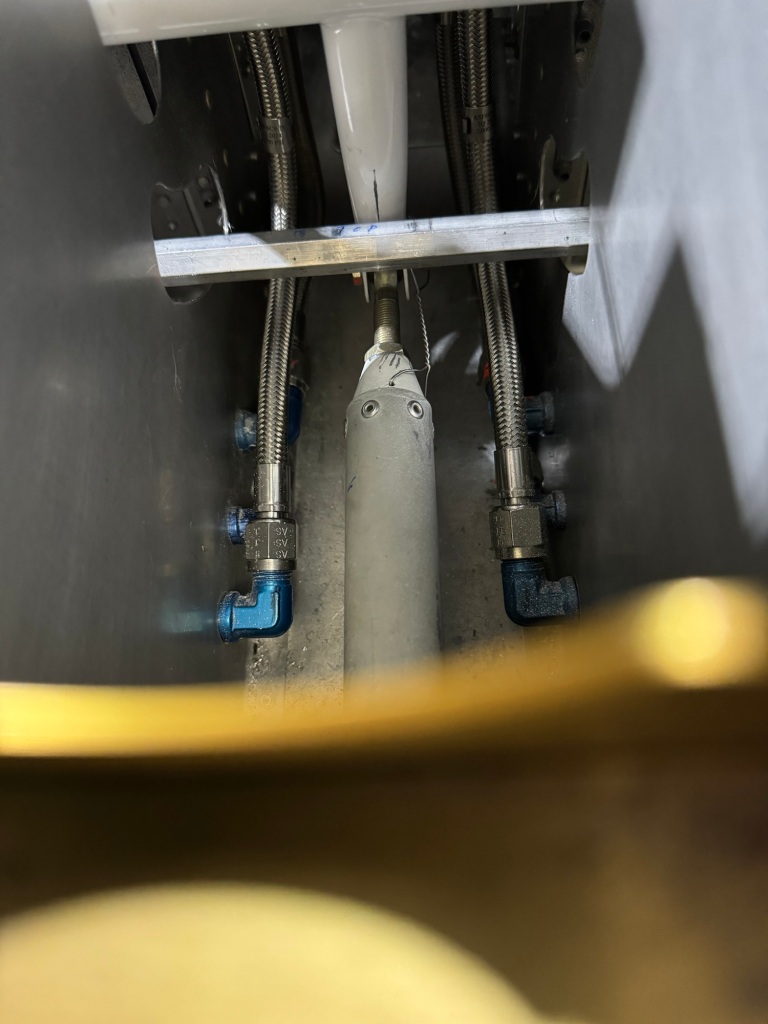

I test fit the fuel supply and return lines in the wing roots. Everything looked good once I clocked the sidewall bulkhead fitting downward a bit. I plan to put some tubing on the fuel line to avoid abrading the spar and side skins.

I then went down the road of finalizing my rigging. Everything went well except for my elevator rigging, which was somewhat expected. I was fighting a couple of different things. The first was that my stick hits the switches on the Aerosport panel, like so many before me. Some end up bending their stick to get more clearance. I decided to solve it by adjusting the forward and aft stops as well as changing the aft rod end of the forward (F-1089) pushrod from a MD3614M to a MD3616M to get more thread length to allow me to unscrew it more, resulting in the stick not going as far forward, while still having enough thread engaged in the pushrod.

Additionally, I was very close to needing to do the elevator stop service bulletin. So I took the opportunity to do that as well. To do these changes, I needed to take the rudder and Vertical Stab off to get better access.

I also installed a forward stop as well to help further limit the down stick travel by limiting elevator down travel to the min of 20 degrees.

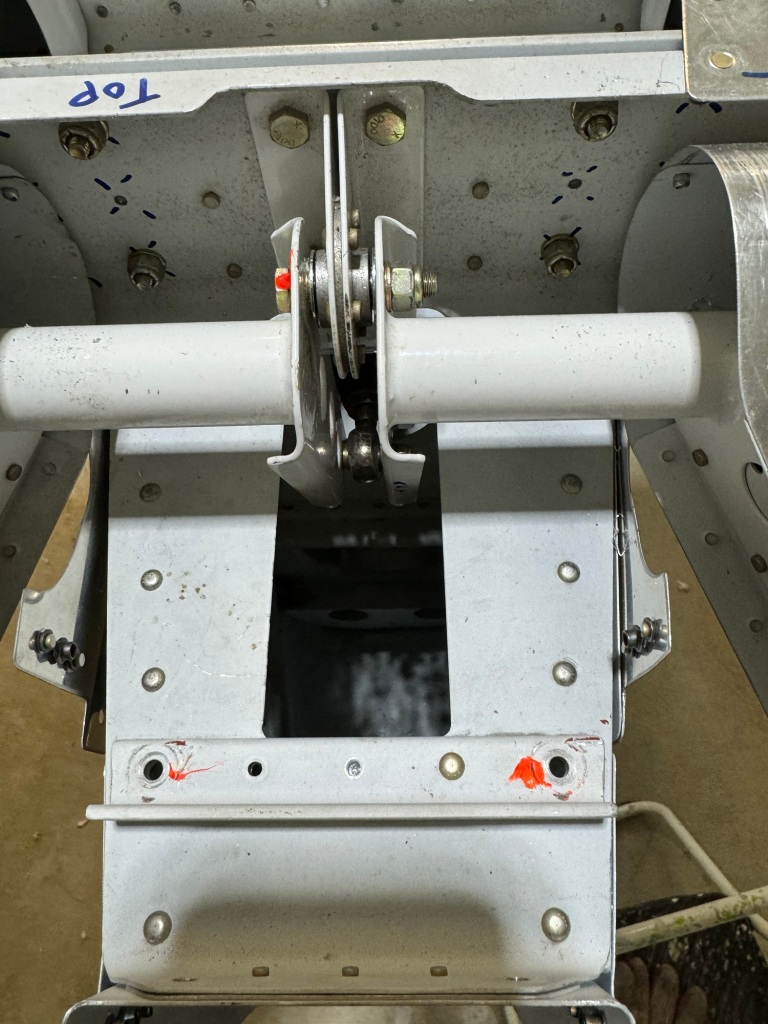

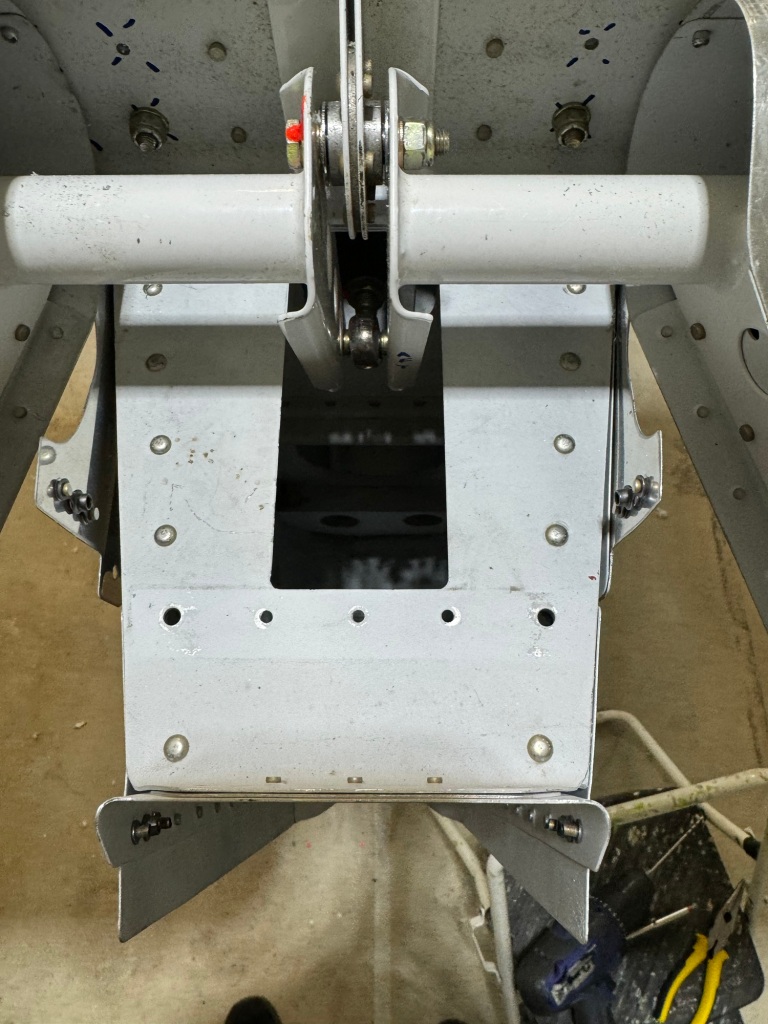

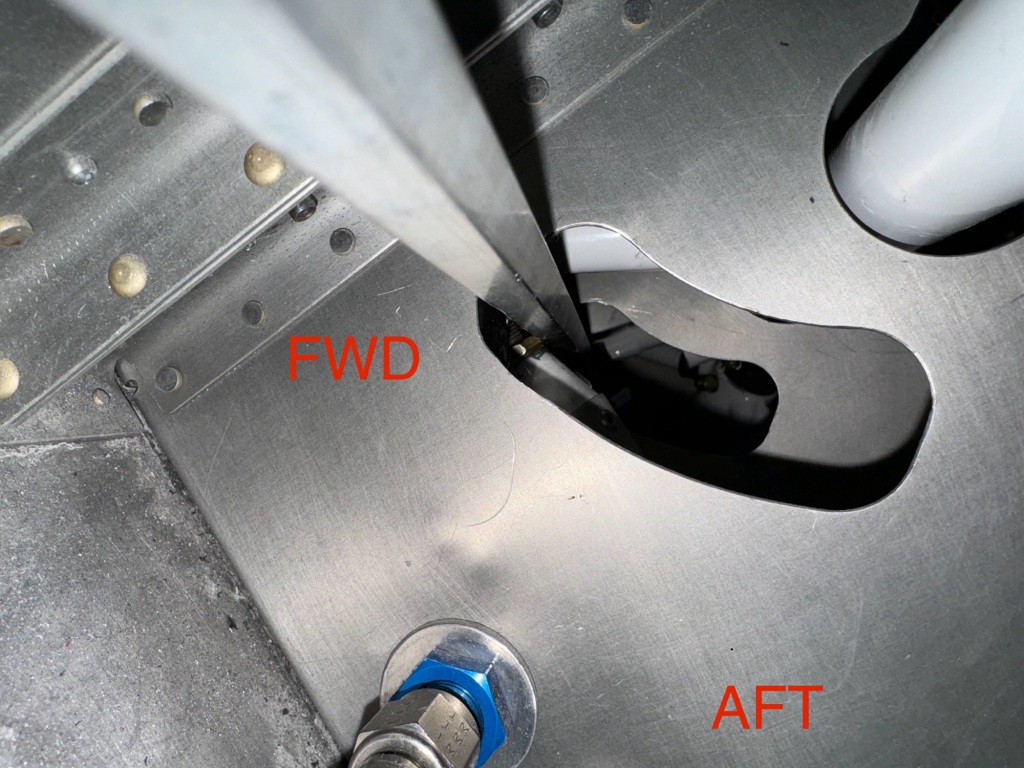

I then battled another issue with the control stick travel and a bolt head hitting the control column mount. This seems to be due to the angle of the stick weldment not being 70 degrees. It is causing the travel in the space cutout for the aileron pushrod to be biased forward as shown below.

Van’s tells me that this is usually due to the pushrod lengths being off. So I spent a ton of time removing all 3 of my pushrods and re-checking their lengths. They were really close as they were. Then working on setting things up properly from aft to front. At the end of the day, even with the stock measurements of the pushrods, I still have the same issue, so that is not the root cause.

Below I show the interference with the bolt and the mount.

So I decided to carve out a half moon as shown above in the mount to create clearance for the bolt. At least one other builder has told me they have seen this a bunch of times and done the same thing.

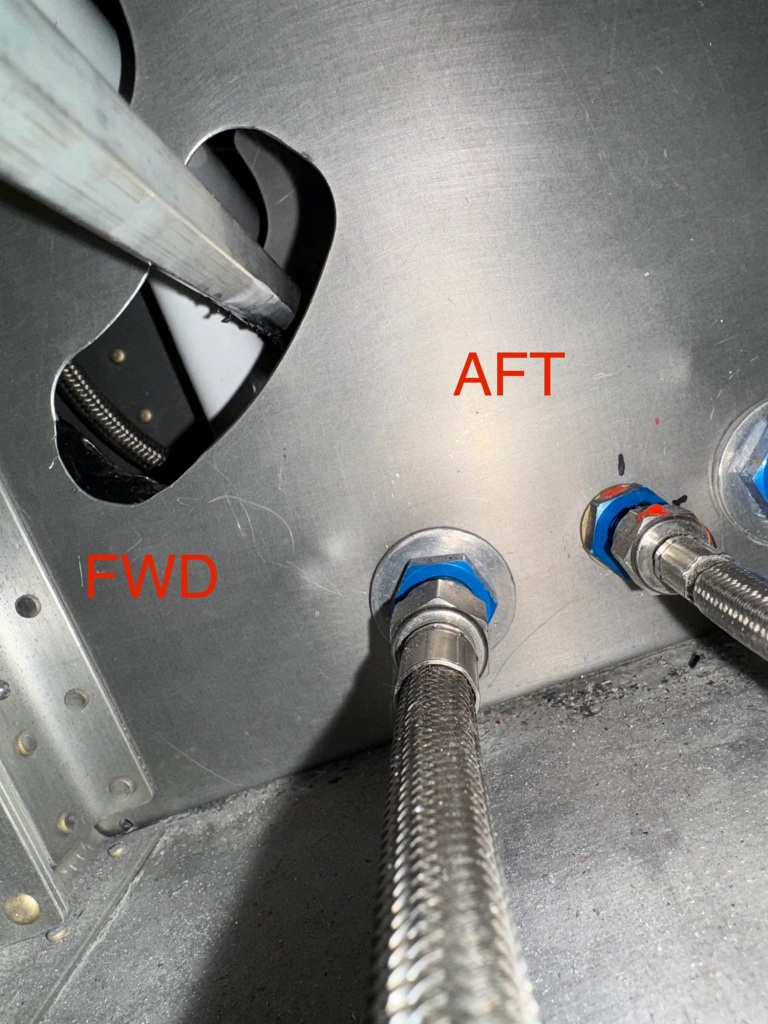

One other problem that resulted from this forward bias, is that the aileron pushrod that connects the 2 sticks through the tunnel was rubbing on my fuel lines as shown in the video below.

There was no possible way to move the lines forward anymore due to me having a brake line in the way.

In talking with Tom, I asked him to make 2 new lines for me that were 1/2″ longer to solve this issue.

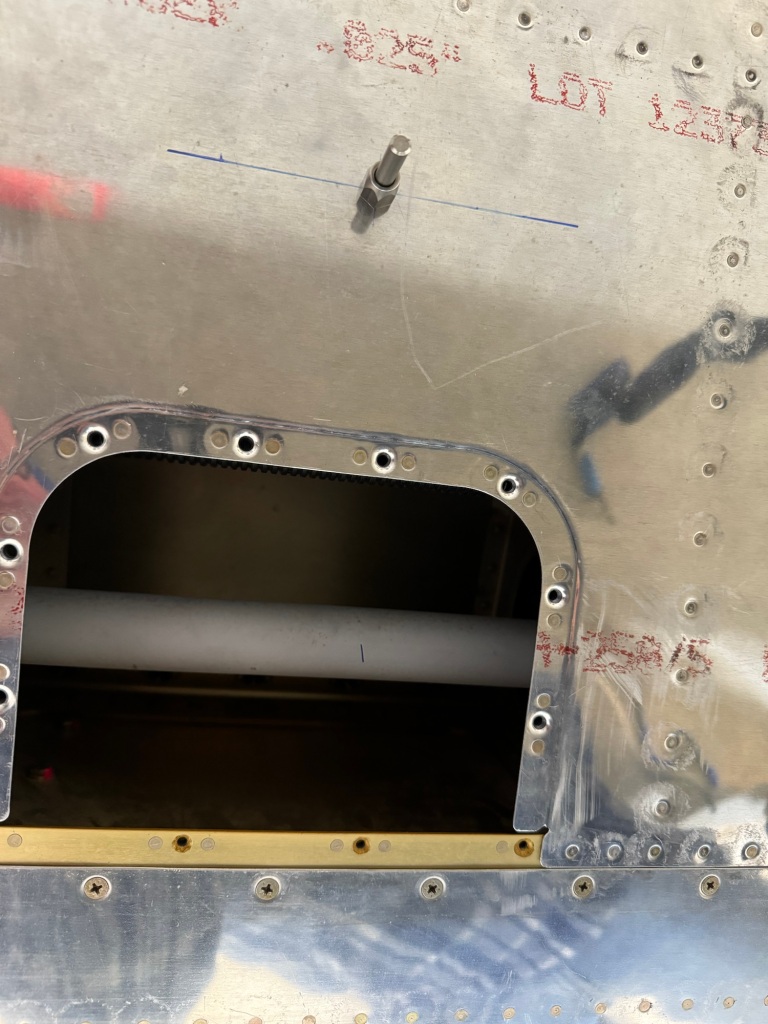

With that saga behind me, I then bolted the wings on permanently. There are 8 bolts holding each wing on.

I also finished wiring the wings. Below is the air temp sensor under the 2nd access panel on the right wing.

Wingtips were also installed and tested out.

Now there are a couple of things left to finish up and then it’s time to get ready for my inspection. Calibrating gauges, fuel tanks, doing fuel flow tests, etc…