Some additional tasks to finish up in prep to move to the airport.. Below you can see the small wrench I had to grind down in order to fit into the very tight spot and tighten the top arm of the main alternator. This had to be done after the prop was installed.

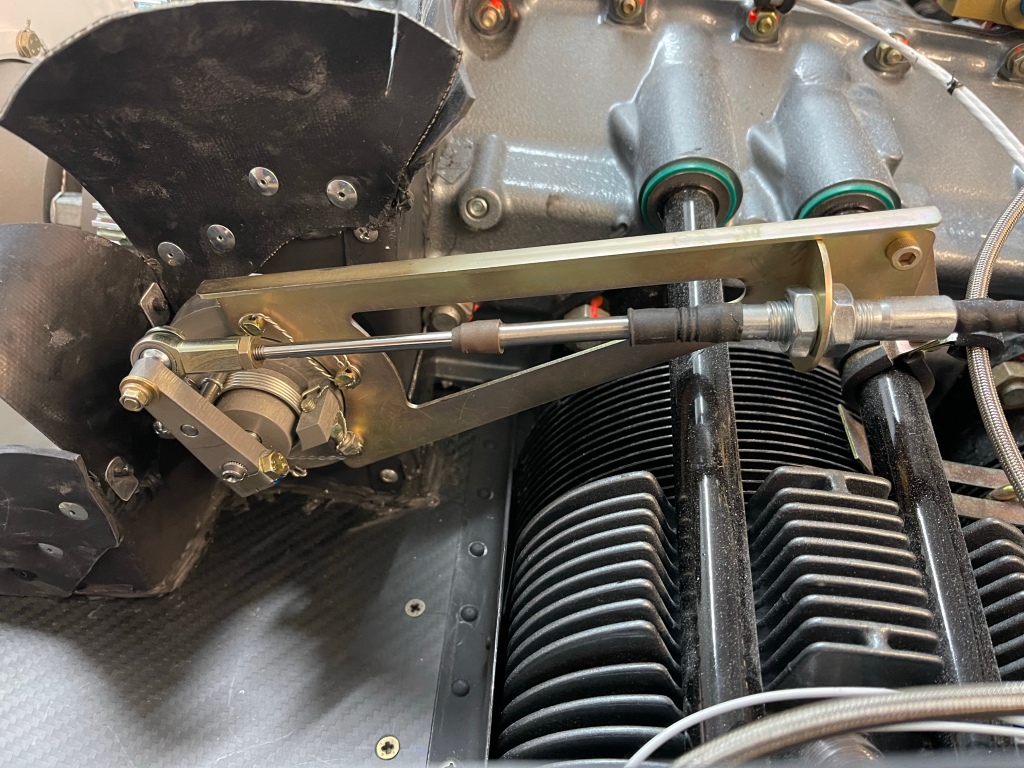

I had another tech councilor visit and he reviewed my FWF wiring/plumbing. A couple of minor suggestions for changes were made. One thing we discussed is getting the prop governor cable able to hit the stops on the governor itself before the lever in the throttle quadrant hits. I was having a hard time with this specifically. No matter what I did I could adjust one way and hit that stop, but not the other and vice versa. In the end I was able to rotate the face of the governor after removing the safety wire and loosening the face plate screws to fix the cable geometry issue. It just couldn’t pull aft and downward.

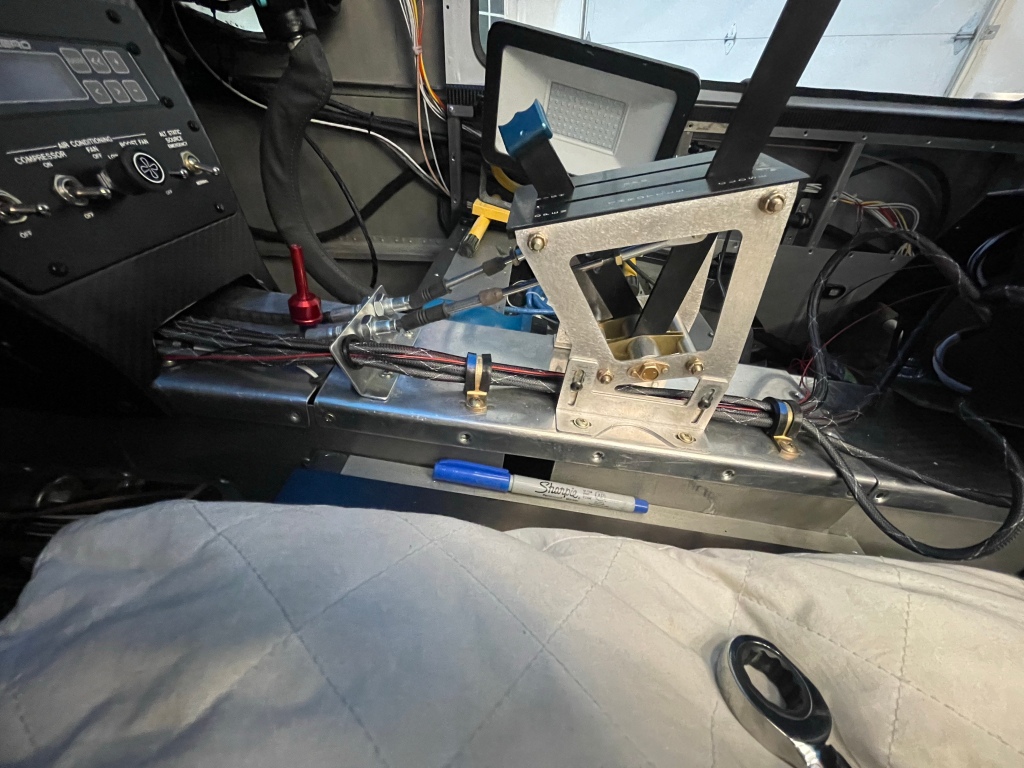

I also needed to get the AC hoses hooked up to the compressor and the dryer. In order to do this and charge later, I wanted to make sure that a vacuum could be held and that there were no leaks. I followed the procedure in the Airflow systems manual for evacuating the system. I hooked my gauges into the high and low side hose ports and pulled a vacuum on the system. I let that run for 10-15 minutes and then shut the vacuum pump off and let things sit for 30 minutes.

I also built and installed my light control circuit that turns the lights on when the doors open. Quick couple pictures with the main flood light and baggage area flood lights turned on by that circuit.

I the completely buttoned up the airplane for transport, getting the aft skin in place, cowling on, and speed tape on major openings because rain was in the forecast.

Then the day came.. I got the plane moved around so I could get it out the middle door of the garage.

Not the best day.. A decent example of the rain before we started loading and the speed tape doing a decent job of keeping it out of the plane.

I helped the driver get the plane in position and also kept the nose wheel straight with the tow bar as we pull the plane up onto the ramp. With the castering nose wheel, this really needed to be done to keep the plane coming up the ramp straight.

Now work has started on getting the tail pieces on. I’m still finishing up the wings bottom skins and ZipTips at home. It’ll be good to be able to work some at the hangar on the emp, while I still make some progress at night from home for the next few weeks.