I needed to decide on whether to put the pre-filters for the fuel lines under my seats or in the tunnel. Tom at TS Flight Lines had suggested 2 methods. Either a single pre-filter and post-filter mounted above the fuel pump module, or have 2 pre-filters one for each supply line under my seats. In either case, the post-filter would be in the tunnel. Advantages of under the seats are that less room in the already tight tunnel would be taken up. Some also may argue ease of maintenance, although I’m not 100% sold on that. The cons are that attaching the pre-filters to the tunnel bulkhead fittings as Tom leaned towards (which allows for a single hose assembly from the fuel tanks to the pre-filters) was causing lots of extra work. The pre-filter in that location interfered with the systems bracket that holds the lines in place off the bottom skins. I was going to have to cut that partially out to make room for the filter and also adjust the top part of the bracket too to fasten to the modified lower half of the bracket.

Advantages to filters in the tunnel are: there is only 1 pre filter module (less cost) and less modifications, saving time. The main downside is that it takes up more room in the tunnel.

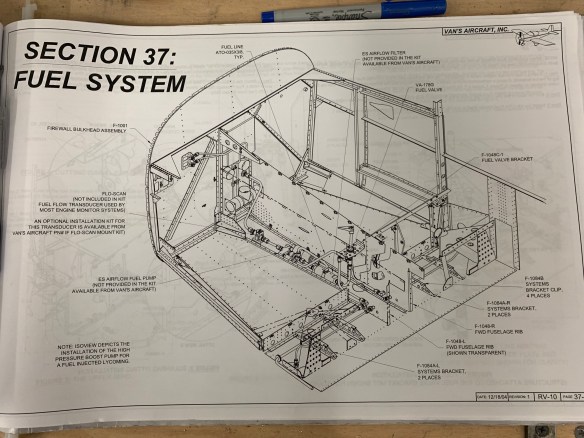

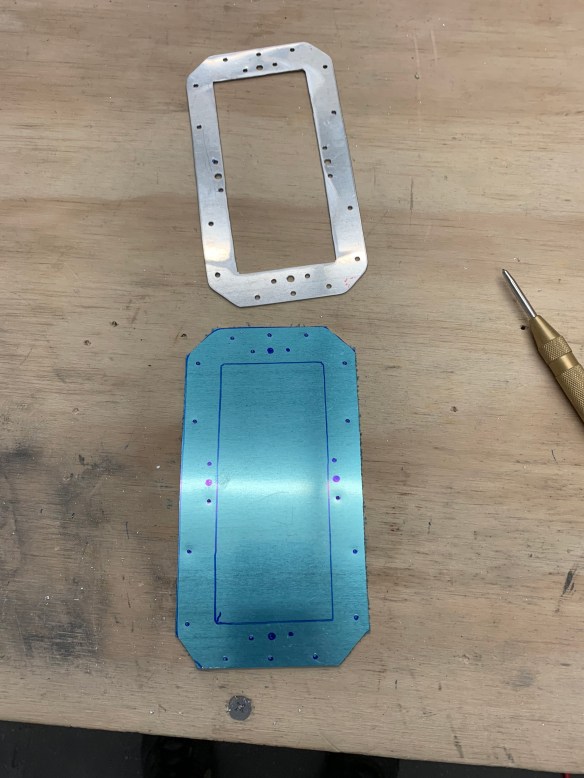

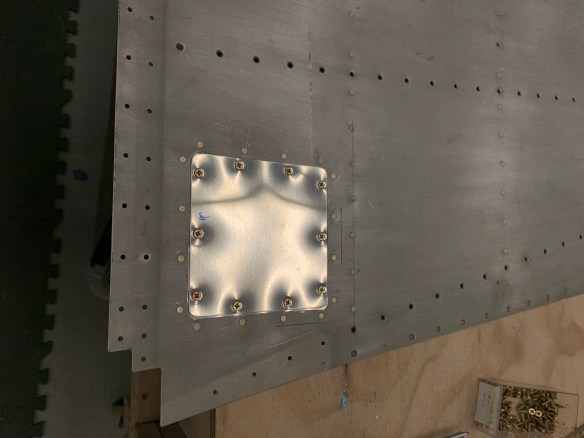

Below are pictures of the 2 methods:

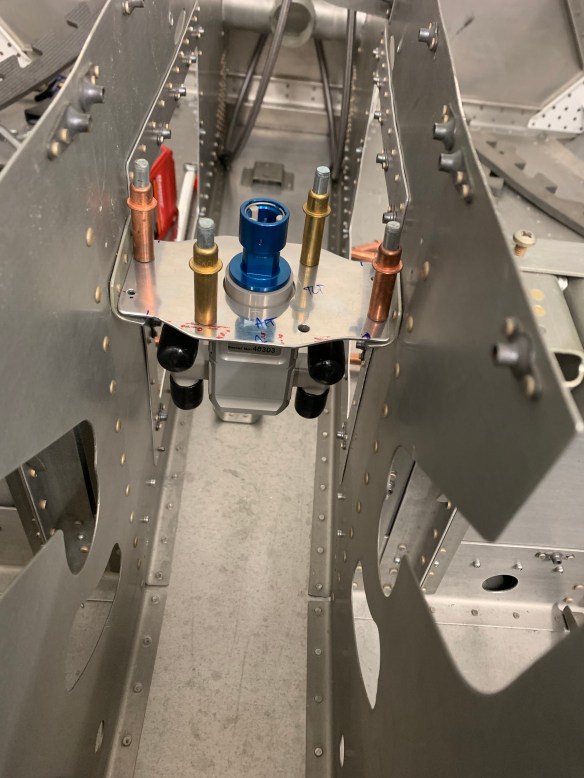

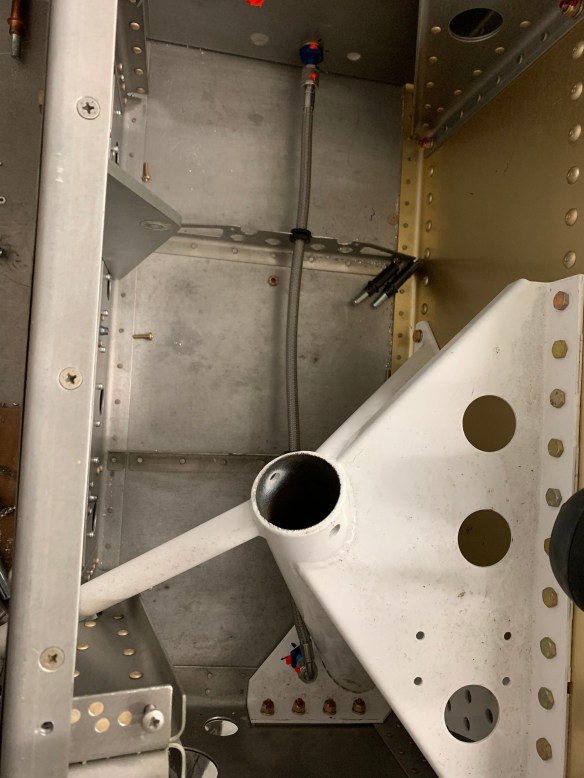

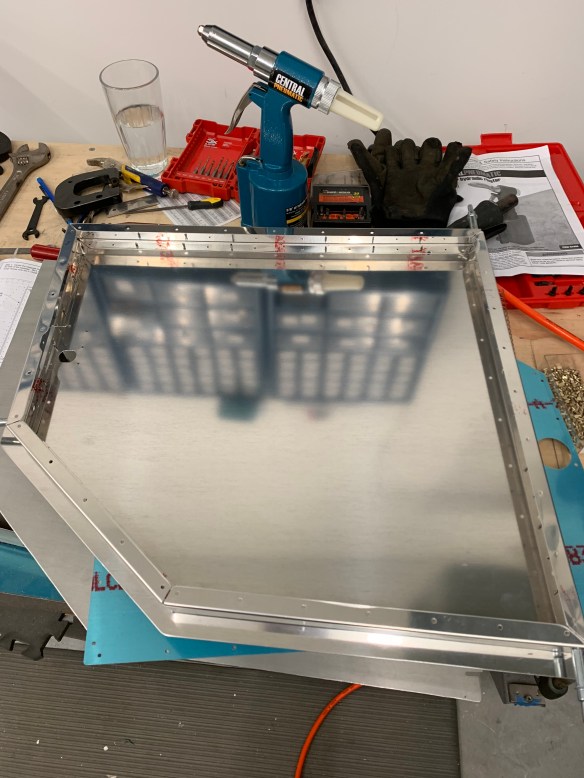

Method 1: Under the seats

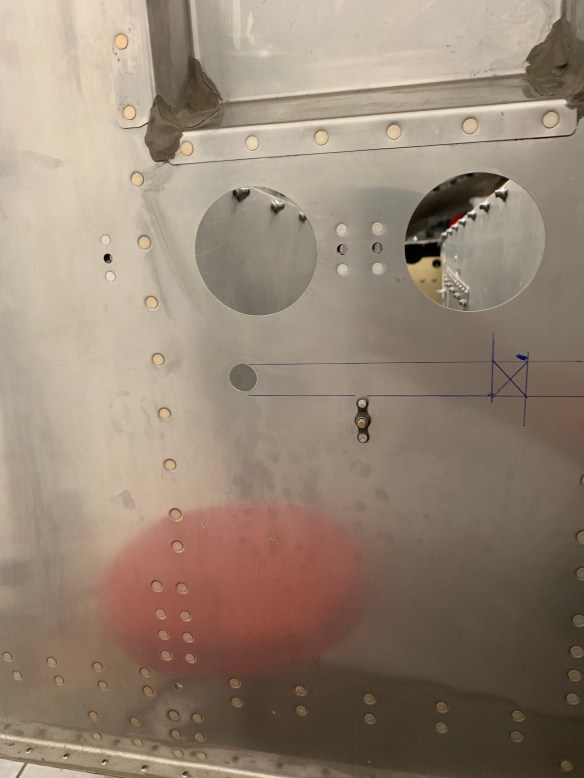

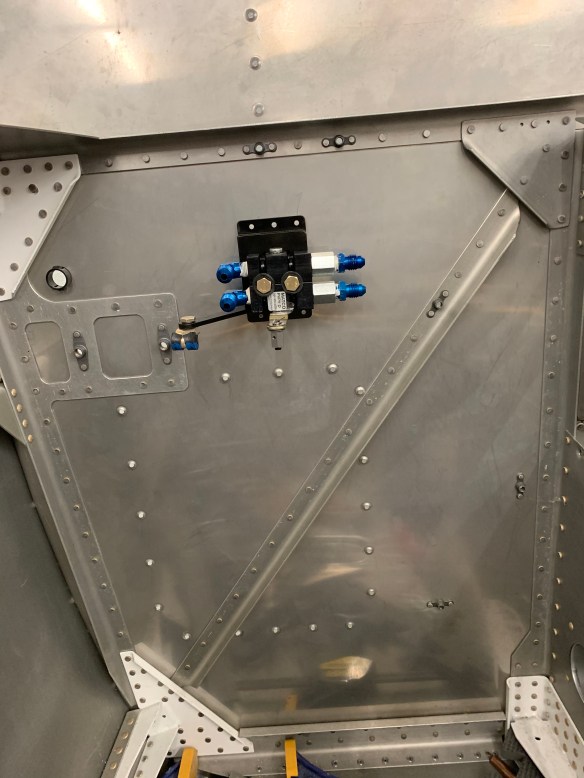

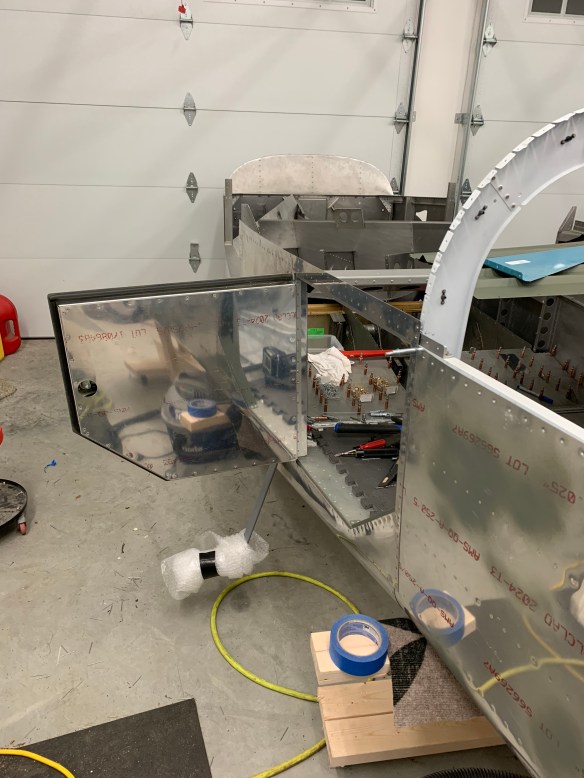

Method 2: In the tunnel as part of the pump module assembly (Adel clamps to hold it together are missing here)

I ended up going with method 2. With this method, the pump module will actually be installed backwards in the sense that fuel flow will be going forward to aft (or top to bottom as shown in the picture above as the firewall would be towards the top of the picture). The idea here is a hose will connect the valve selector to the pre-filter on the left. Flow through the pump module and into the post-filter on the right. Then a hose will connect from the output of the post-filter to the firewall fitting to the engine. I liked the idea of a self contained unit, which required less hacking of the existing structure to make it work, and seeing I made the aluminum plate that the pump module sits on removable with 6 screws, maintenance should be as easy as removing 2 hoses (in and out) from the filters, unscrew the plate, and remove the whole assembly to work on it on a bench.

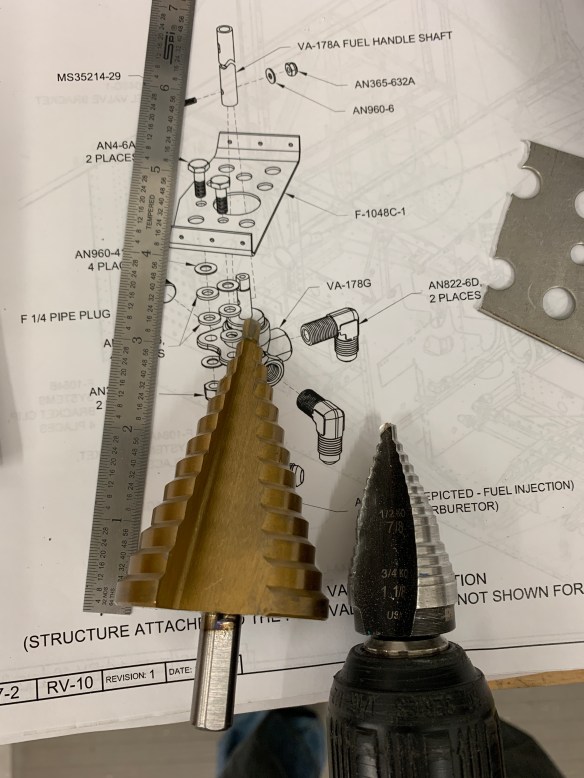

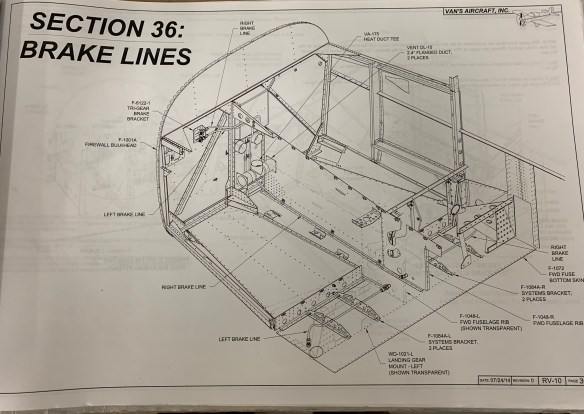

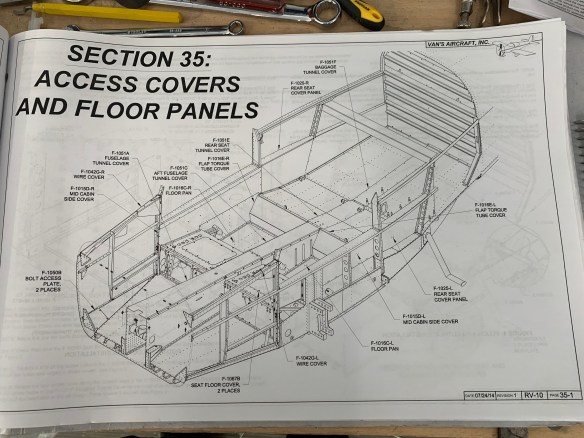

I then ordered my fuel line hoses after making that choice. In the interim, I started working on the rudder pedal section of the plans.

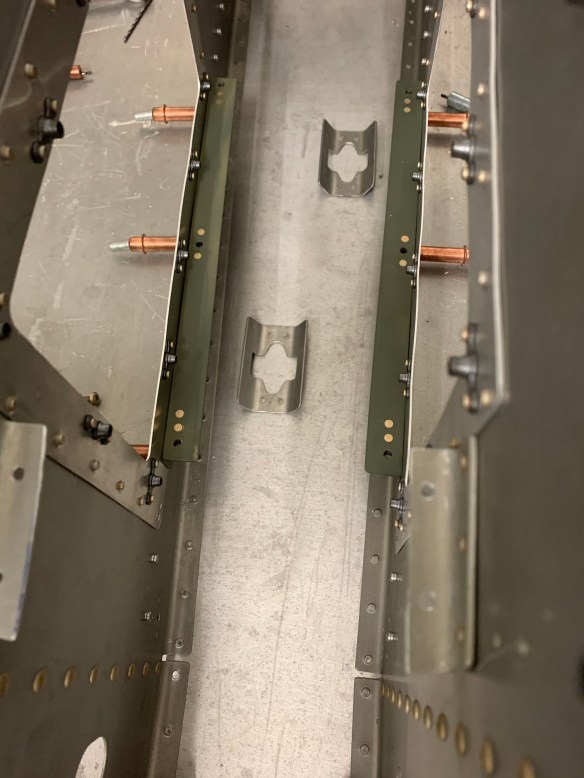

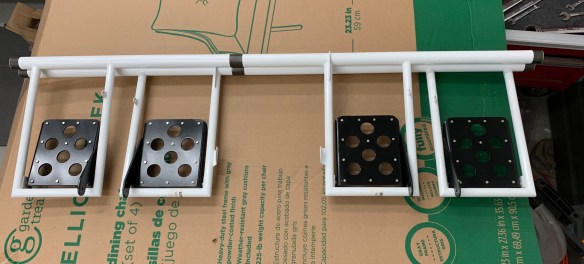

I prepped, primed, painted, and riveted the pedal assemblies, then attached them to the powder coated arms that span the width of the airplane.

I then attached the master brake cylinders to each pedal and inserted the fittings into the cylinders. Note a few are missing here in this picture. One of the pitfalls of going off plans. Seeing I’m using the flexible lines, I didn’t have enough AN822-4D fittings for all the holes, as Van’s provides some brass fittings which are intended for their way of doing the lines. Seems every time I turn around I need to order something new from Aircraft Spruce… Guess I’ll keep them in business.

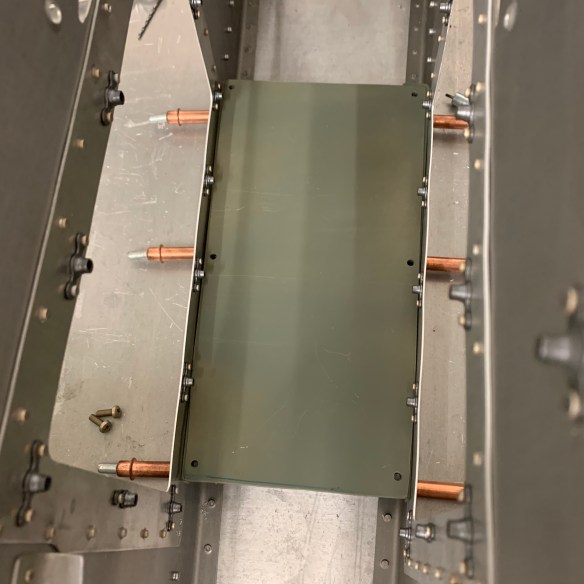

Rudder pedal assembly in place temporarily

Some time away from the shop on a long weekend away in Kansas, and a bunch of items came in. My fuel lines, and a bunch of stuff from Aerosport including rudder pedal extensions, throttle quadrant, carbon fiber center console, and a NACA vent controller for controlling air to the overhead console vents.

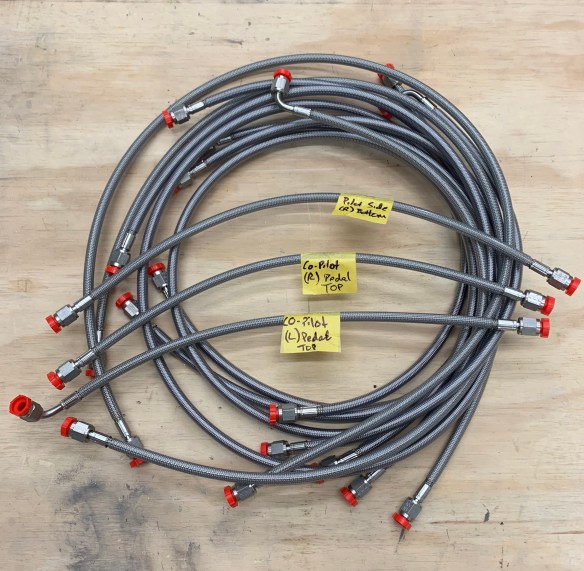

Fuel lines! (all except 2 which I need to measure for)

NACA vent controller (bottom), Throttle quadrant, and rudder pedal extensions

Center console in approx location.

Fuel selector placed in approx location between the seats

So for now it’ll be back to finishing up the fuel system before completing the rudder pedal section.