As I’ve mentioned previously when putting a fuel return port into my gas tanks, I plan to go full EFII (Electronic fuel injection and ignition). That means I’ll have an electrically dependent airplane and, being such, demands quite a bit of attention to the electrical architecture to have redundancy to always keep the fan turning. Fortunately, there is a guy by the name of Bob Nuckolls over at the AeroElectric Connection who has written a book outlining basic electrical principles (most of which I already know being an EE), and provides multiple different time-proven architectures having worked in the industry for many years.

Early on, I had really settled on his Z-14 architecture, which is a dual battery, dual alternator, split (redundant) bus architecture. In-depth schematics are located across 2 pages here and here for those interested. This allows one to take approx half of the load and run it on one bus independent from the other. The idea would be to have the left glass panel, #1Nav/Com, and a handful of other goodies on one bus, and have the #2 Nav/Com, the right-most glass panel etc.. on the other bus. That way you should always be able to navigate, communicate, and get on the ground even under IMC conditions. Additionally, the EFII system is redundant too in the sense that there are 2 ECU modules, 2 fuel pumps, 2 ignition coils, etc… so each of those would be powered off of their respective redundant power busses such that you always have power to at least one of the redundant pair. The 2 busses also have the ability to crossfeed, meaning that if a failure occurs which takes out one bus, it’s possible to continue to use it by having the 2nd bus feed it. That feed won’t be at the same overall capacity as you are now on a single battery and alternator, but most stuff should be able to be used after doing some non-critical load shedding.

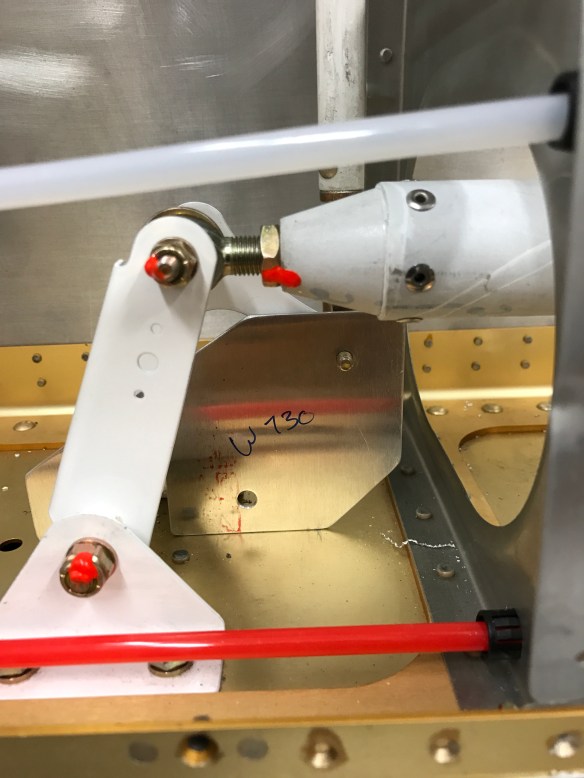

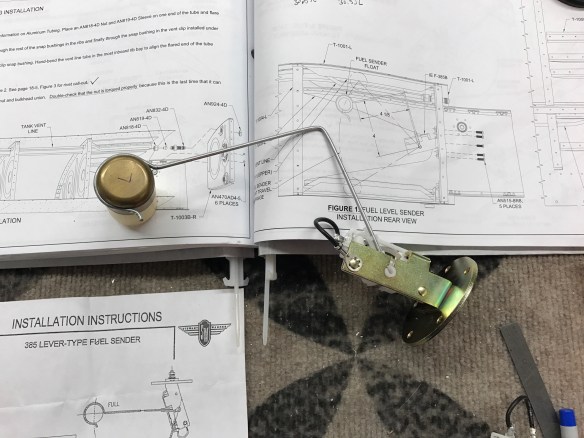

I’m getting close to pluming in my brake and fuel lines and systems so I’ve recently started researching more details into the architecture and also the SDS EFII solution I have chosen. First off, I’ve ordered the Andair duplex fuel selector that I’ll need to both select and return fuel from one of the tanks.

Duplex fuel selector

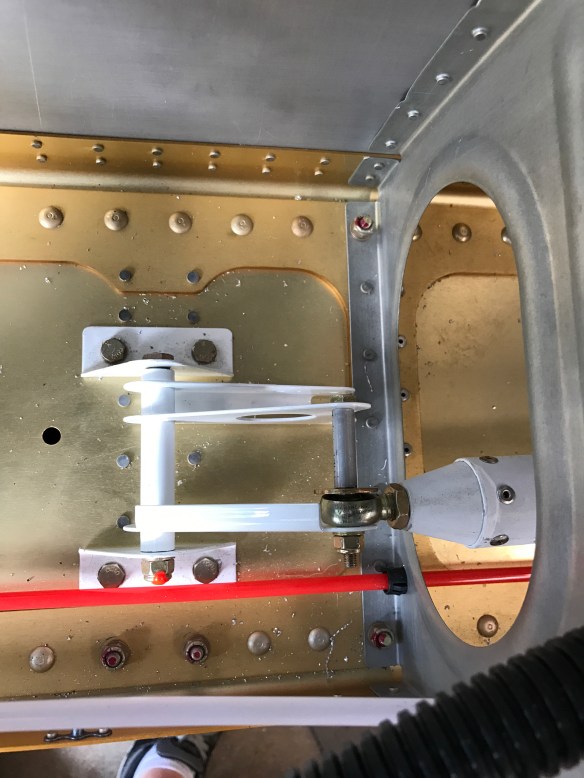

I’ve also placed an order for my dual fuel pump module (shown below), filters, and pressure regulator.

Dual fuel pump

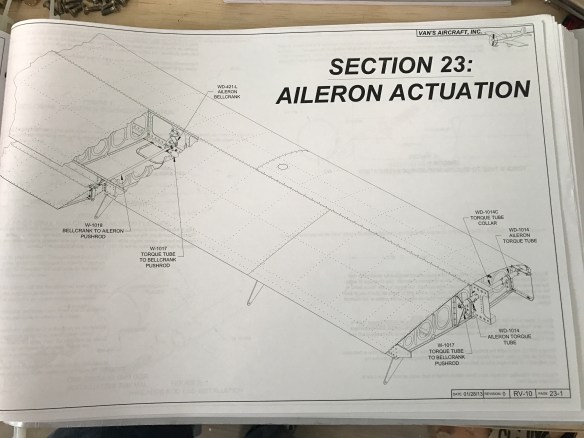

One thing that I have discovered is the fact that there is only one set of injectors into each engine cylinder for the fuel injection (i.e. not redundant), so there becomes a need to be able to power those devices from either battery. I was figuring that I was going to need to diode-Or the two battery busses together in order to accomplish that. Fortunately there was some really good discussion on VAF about this very topic and various architectures for an EFII setup. The end result was a slightly modified Z14 architecture that provides just that. I am currently planning on going with this as the architecture for my plane.

Z14 Electrical Architecture with addition of Diode-OR’ed Engine Bus

Credit for the diagram goes to Dan Horton.

Ignore the alternator amperages for now. I will need to work out my exact electrical loading and size everything appropriately.

Talking to the architecture diagram, you have 2 separate batteries that provide their respective battery busses. These feeds are directly off the battery. The battery busses are then joined together via switches and diodes to form an Engine bus. One could simply put the fuel injectors on this engine bus and keep all the other redundant engine components on their respective battery busses, but the point was made that once you have to have an engine bus, you might as well put all critical engine components on it. The switches would provide a way to isolate the engine bus from either side if something really bad happened on one of the sides that it was impacting the engine bus somehow.

The upper part of the diagram shows each battery feeding a a main and aux contactor (what your master switch typically turns on) powering a main and aux bus which all of the other electrical devices will sit on. There is the cross-feed (cross tie) contactor which allows one bus to drive the other, and each bus has its own alternator.

There will be no single point of failure that can cause the engine to shut off, if something happens, the goal of the architecture is to be able to keep flying while diagnosing and planning to get on the ground as soon as practical. Another benefit of this is if there were ever smoke in the cockpit, the first reaction will be to shut off the master switches. This is still the response here. The panel will go dark, but the engine will still run.

There is still lots of work to do on specifics, but I feel like I have a solid foundation to work from.