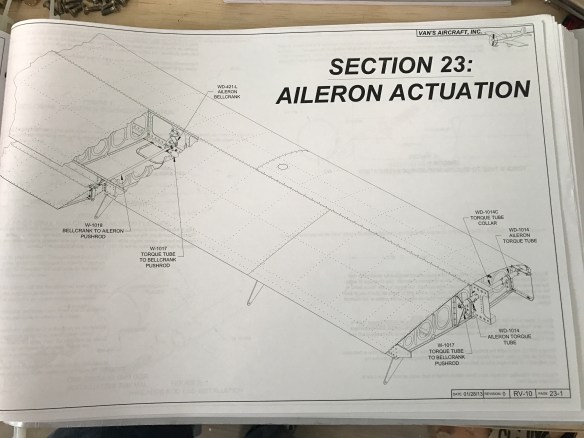

First step in this section is to fabricate two torque tubes which are used to push and pull on a bellcrank mounted on the spar. This bellcrank converts the horizontal motion into fore and aft motion to move the aileron up and down.

Torque tubes and end caps

Drilling holes for the end caps

End caps riveted on

Both tubes completed and aileron torque tube ends shown too.

I then fabricated the bellcrank to aileron pushrods as well as the start of another set of aileron torque tubes which sit at the root of the wing and partly attach to bearings on the end of the gas tank. Seeing I hadn’t yet leak tested my tanks, I needed to take a break and do that, prior to reattaching them to the wings.

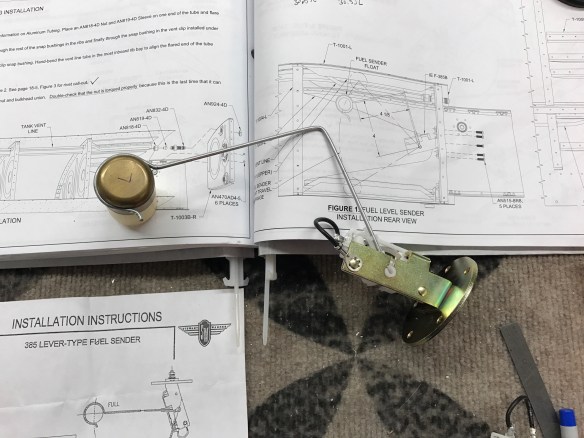

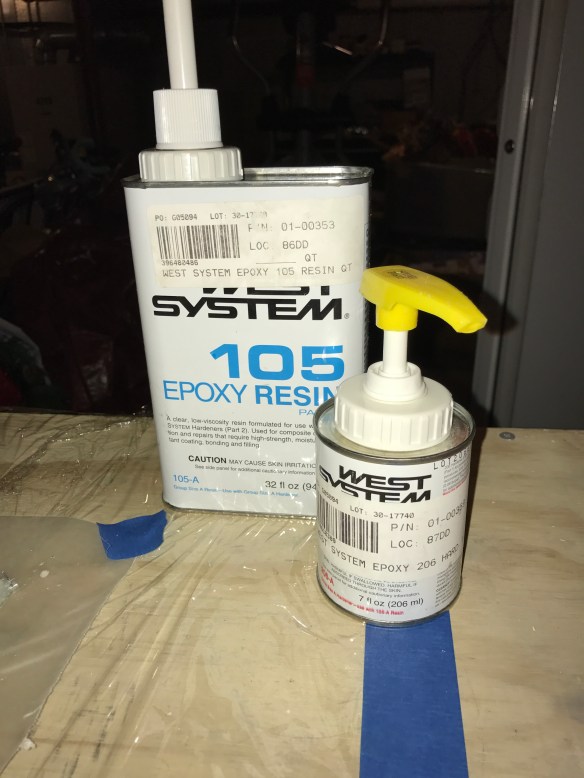

Leak testing the tanks is relatively straightforward. The idea is to seal off all openings, pressurize the tanks just enough (too much pressure can cause damage) and spray soapy water all over the seams and joints to see if there are any leaks. A bicycle pump valve is provided in the kit to go into the fuel drain port. This allows you to use a bicycle pump to inject air into the tank, pressurizing it. The fuel pickup and, in my case, fuel return line needed to be capped off. In order to provide a safety valve, a balloon is placed on the tank vent port and will inflate as you add air into the tank. The balloon acts as a safety valve and will pop prior to allowing too much pressure to be added to the tank.

Adding air to the tank

Spraying all the rivets and surfaces with soapy water

Of course, never doing this before, I wasn’t quite sure what I was supposed to see if there was indeed a leak. On the first tank I attached the balloon to the vent port with duct tape and a zip-tie. It clearly didn’t work very well and the slow leak exhibited itself by really bubbling up.

Balloon connection had a small leak.

On the second attempt, I placed some fuel lube inside the neck of the balloon, used some string to ensure a better connection, along with a ziptie. That seemed to do the trick. No leaks and the balloon stayed inflated overnight.

I then was able to reattach the tanks to the wings and am relieved that the tanks didn’t have any detectable leaks in them.

With that behind me, I was able to get back to getting the aileron control system fully hooked up.

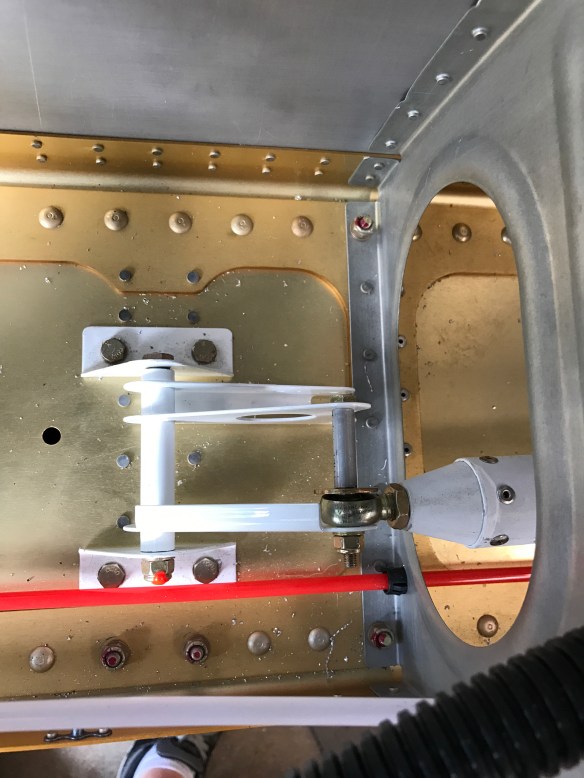

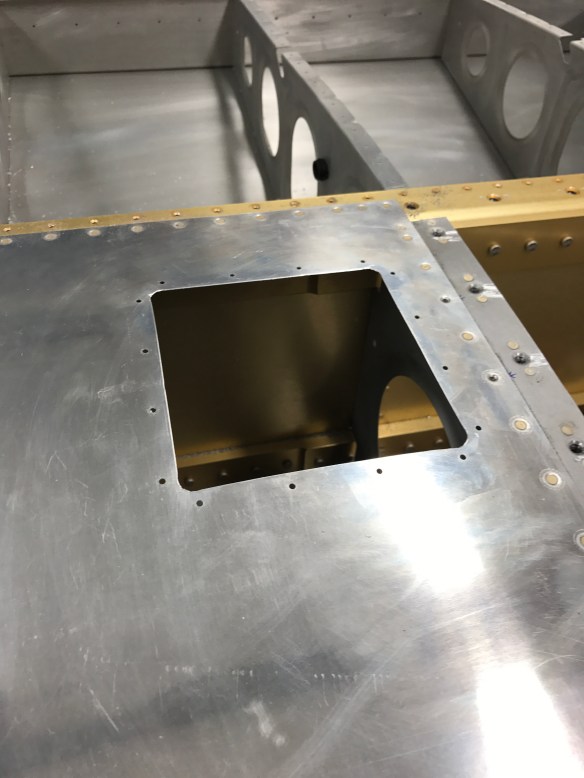

Wing root torque tube attached. Getting ready to attach the main pushrod.

Getting ready to attach the pushrod to the bellcrank

In order to properly set the length of the tube there is a jig that is inserted in the bellcrank that sets the neutral position. One must them make sure that the hole on the arm back at the wing root is exactly 2 9/32″ from the edge of the tank to the center of the hole

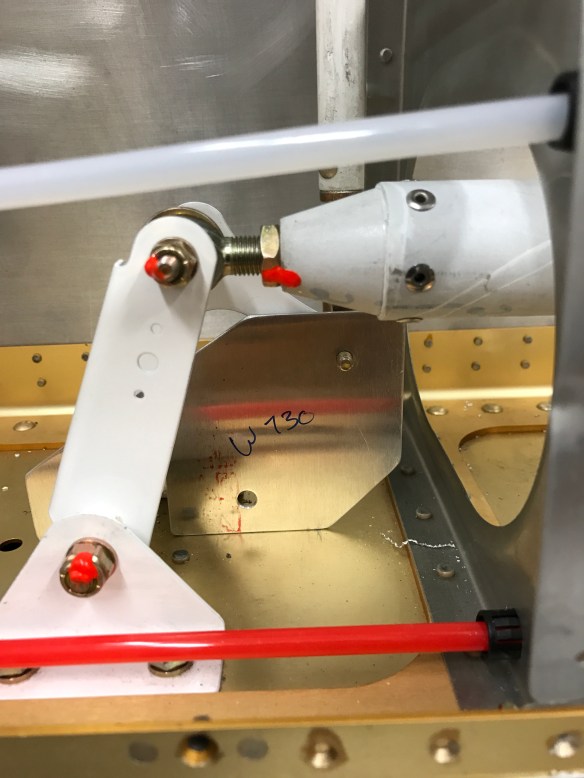

Setting the tube length based on the neutral position with the W-730 Jig

Exactly 2 and 9/32″ to the hole center.

All hooked up, looking down the wing

I then started getting the actual aileron and flaps placed onto the wing to set their neutral position. It is then that I discovered that I had riveted the end of the gap fairing on the wrong way. In setting up the flap position it says that the nose of the flap should sit against the spar doubler. Well instead, mine was sitting against the gap fairing, which didn’t seem correct… I went back in the plans, and sure enough, I did it wrong. Nothing that drilling out a few rivets and flipping it around can’t solve..

That 1021B-L part is not oriented the correct way. DOH!

After drilling out 4 rivets and flipping it around. Much better, and makes more sense.

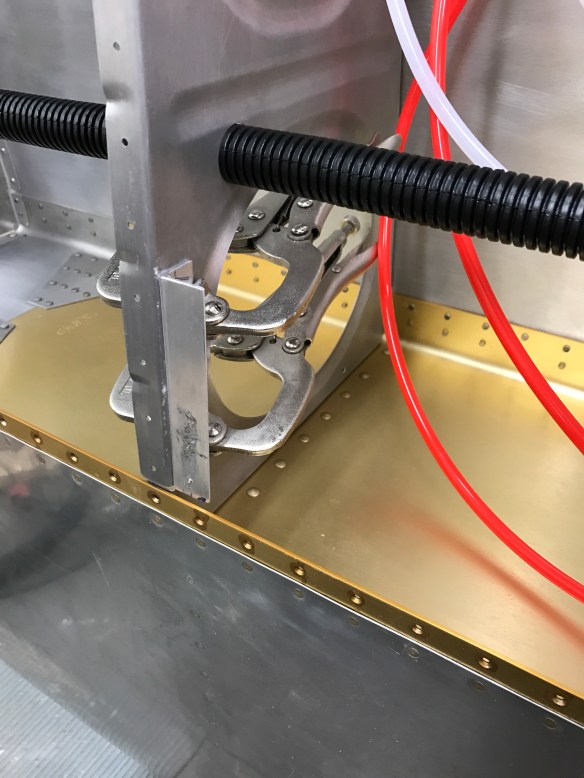

The flap is used to set the neutral position of the aileron by clamping the trailing edges together with some aluminum angle. Then with the W-730 Jig back in place to set the pushrod neutral position, the bellcrank to aileron pushrod length is adjusted so that it is perfectly fits when both items are in their neutral position.

Flap and Aileron clamped together

View of left wing with both flap and aileron installed

Bellcrank to aileron pushrod attached to aileron

W-730 Jig back in place with bolt coming through the pushrod in the upper right of the jig meaning everything is perfectly aligned.

A view looking down at the finalized bellcrank assembly.