Prior to hanging the engine a few odds and ends needed to be completed which are just easier to do beforehand.

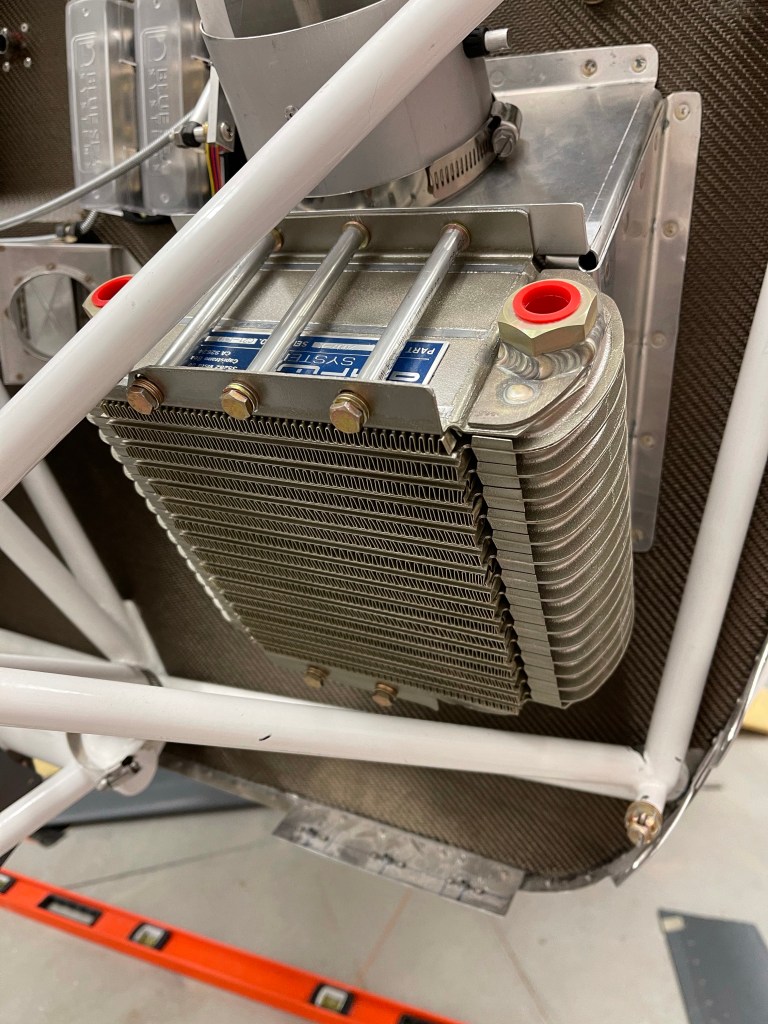

One of those things was adding an angle to the top of the oil cooler mount for the oversized oil cooler. The oil cooler itself needed to have some of its flanges cut to fit around the engine mounts.. Then the angle was cut to length and riveted to the the oil cooler mount. I bolted the bottom bolts into place and drilled holes into the angle for the top 3 bolts.

The end result after ordering long bolts and making some compression tubes to the right length with washers.

I also needed to safety wire the coil pack mounts to the mag cover plates.

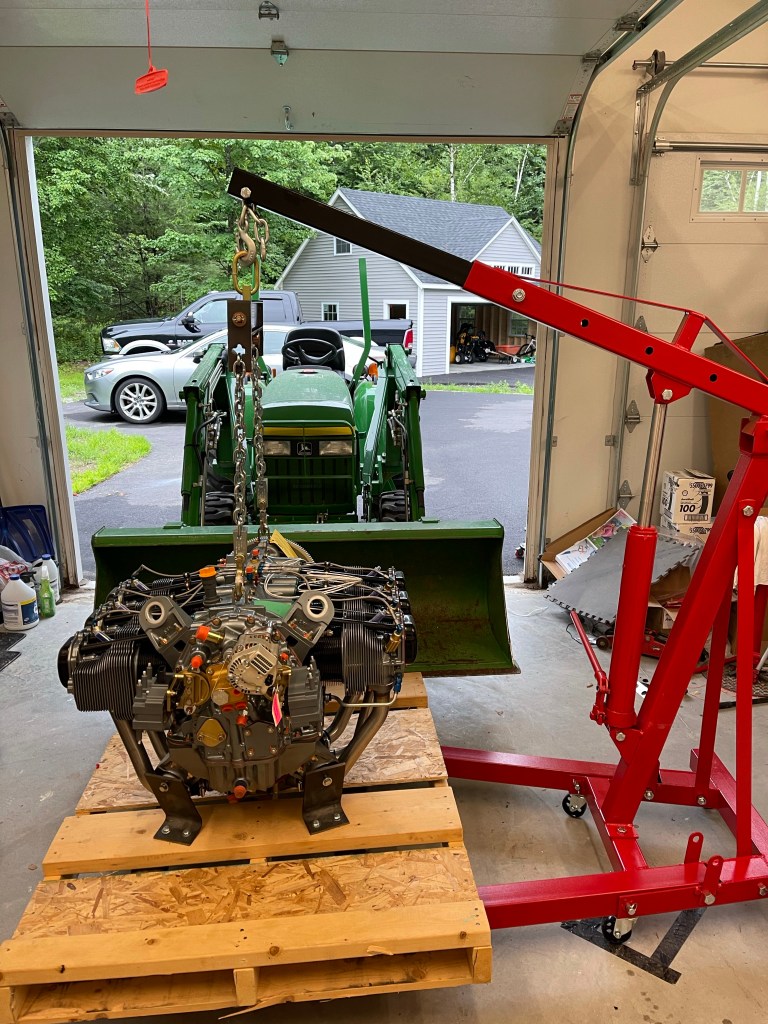

Then came time to install the engine. I used the bucket forks and my tractor to lift the pallet up high enough to get the hoists legs under it.

Then with the hoist connected, I unbolted the engine ears and flywheel from the pallet and lifted the engine up.

The first 2 bolts (top) are the easy ones..

Then it’s a matter of getting the 3rd bolt in, which was a little trickier, but not bad.. The 4th bolt took a bit to get lined up… after a bunch of playing I was able to get the bolt started through the hole and a socket to keep threading it in. Then the engine hoist was removed..

A couple of pics of me with the engine..

Hey Adam, congratulations on achieving this milestone! Looks like you dodged the 13% price increase too.

All the best

LikeLike